- Sorry, this product cannot be purchased.

Products

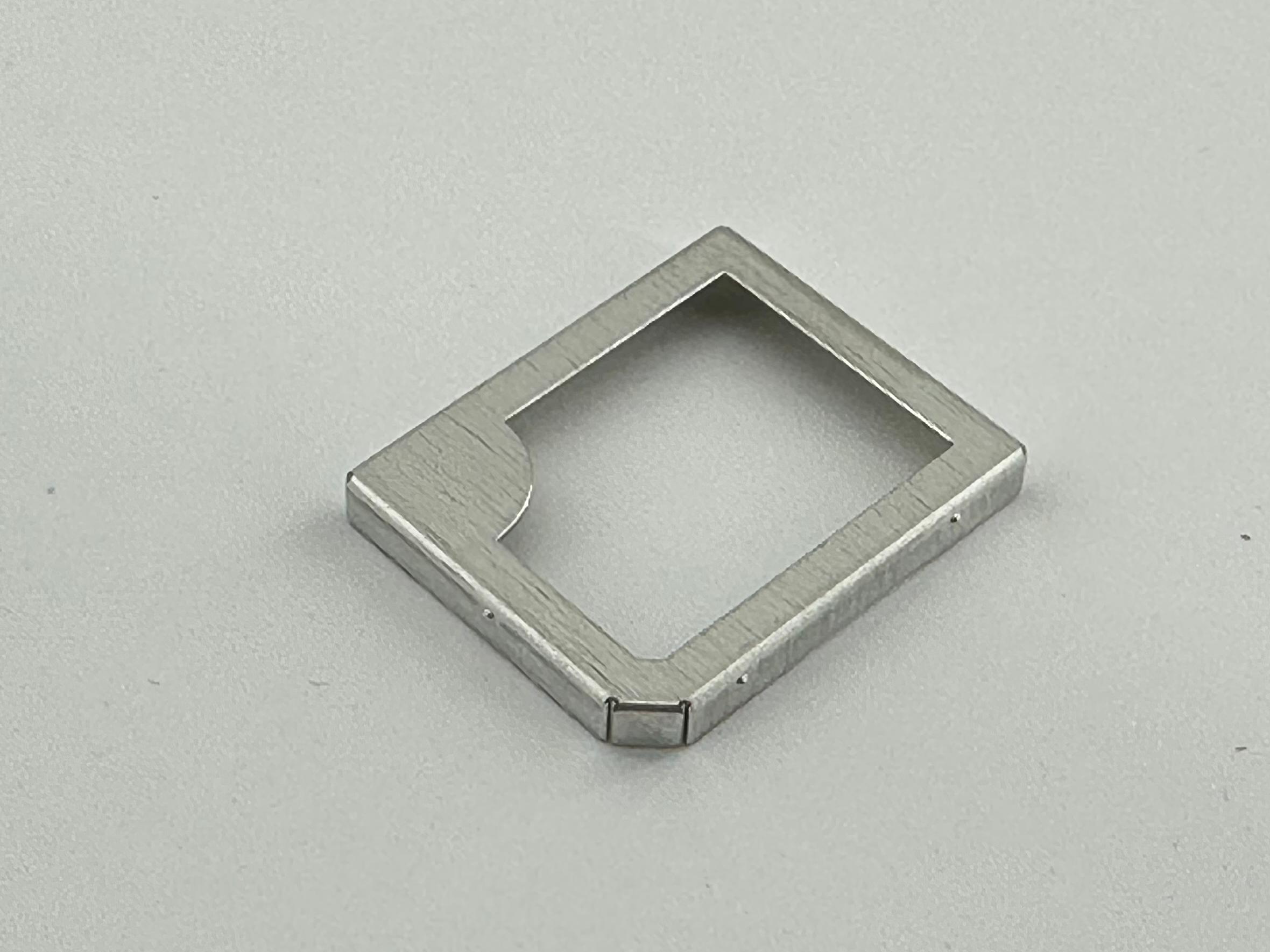

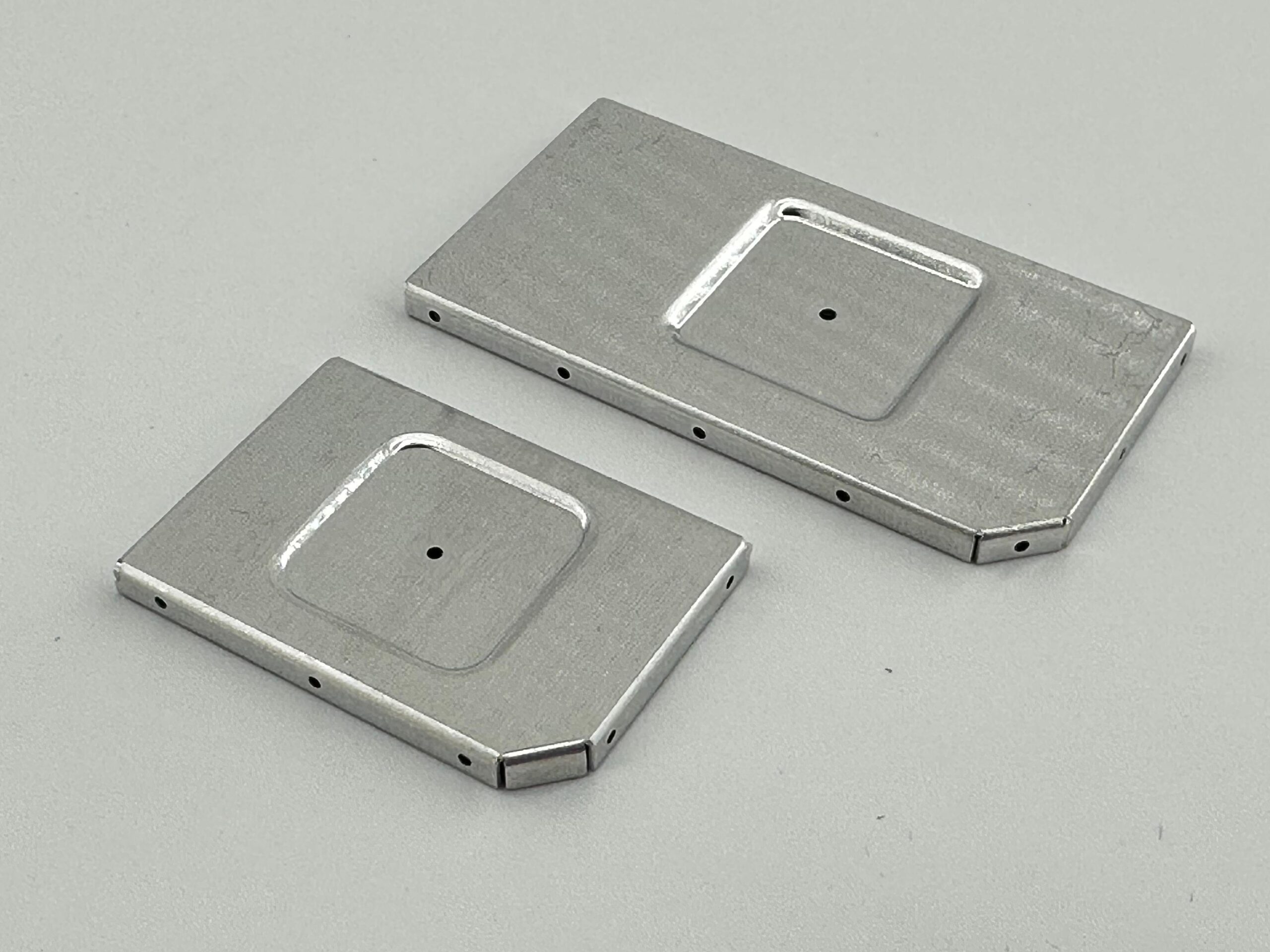

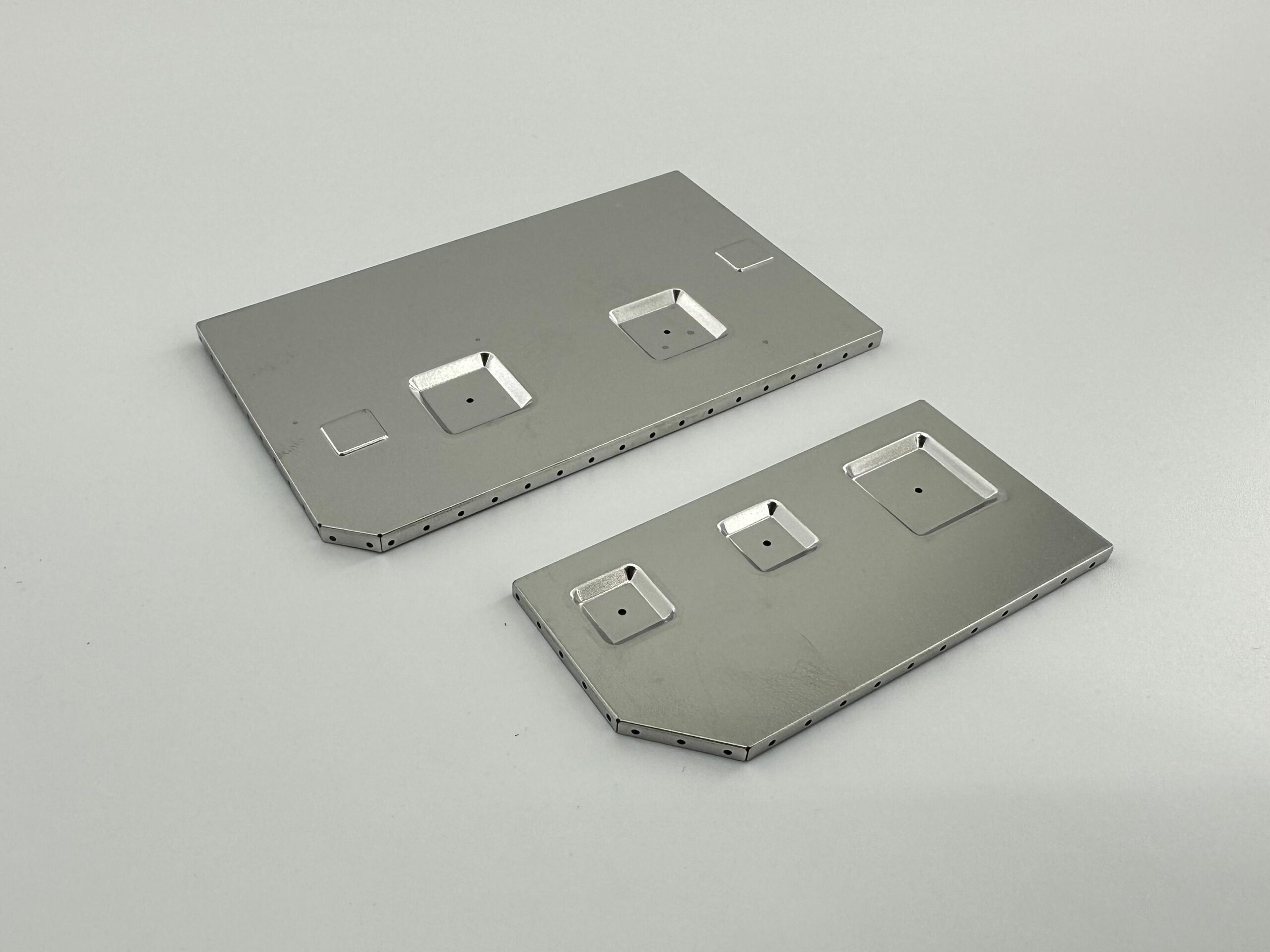

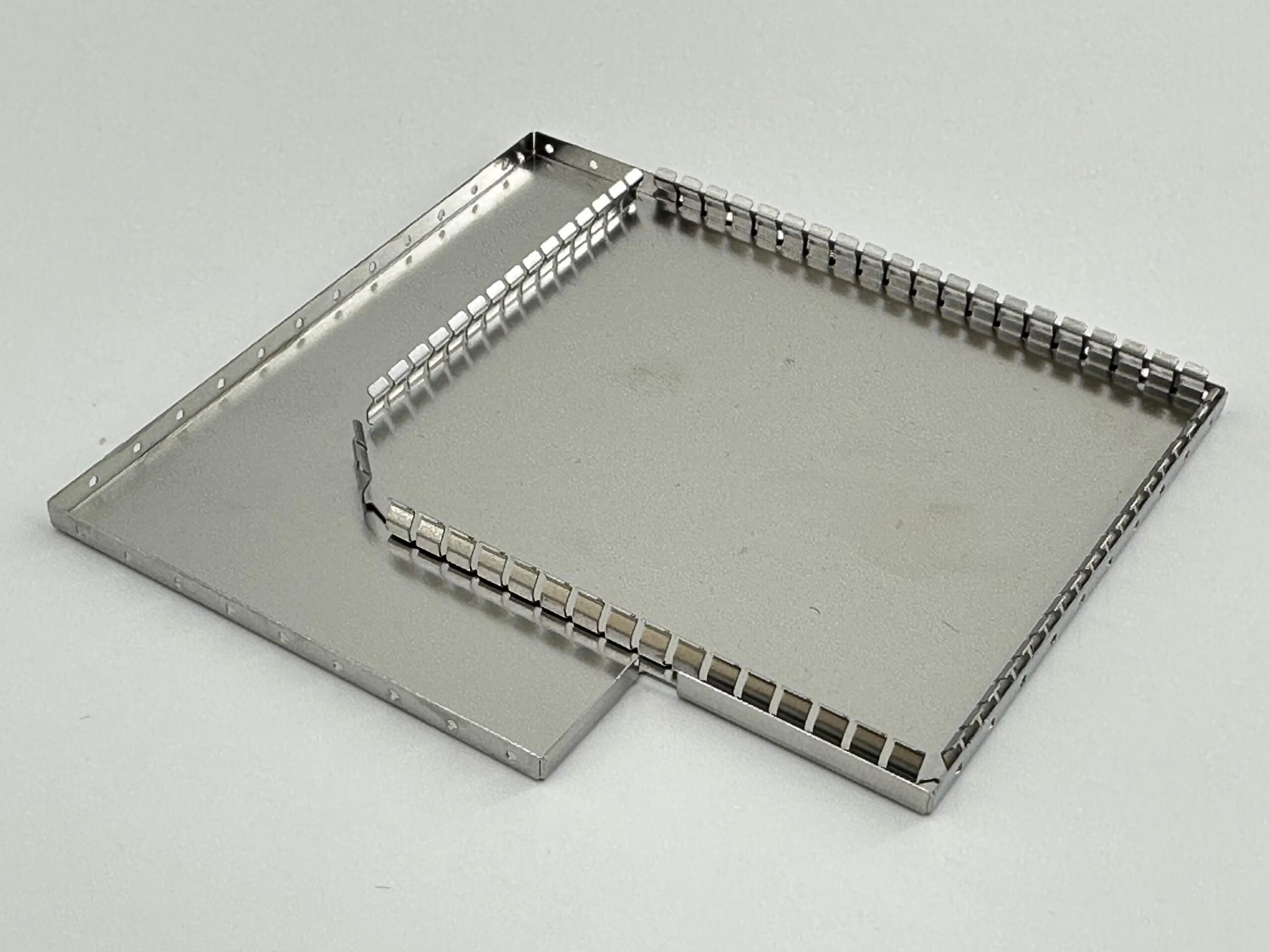

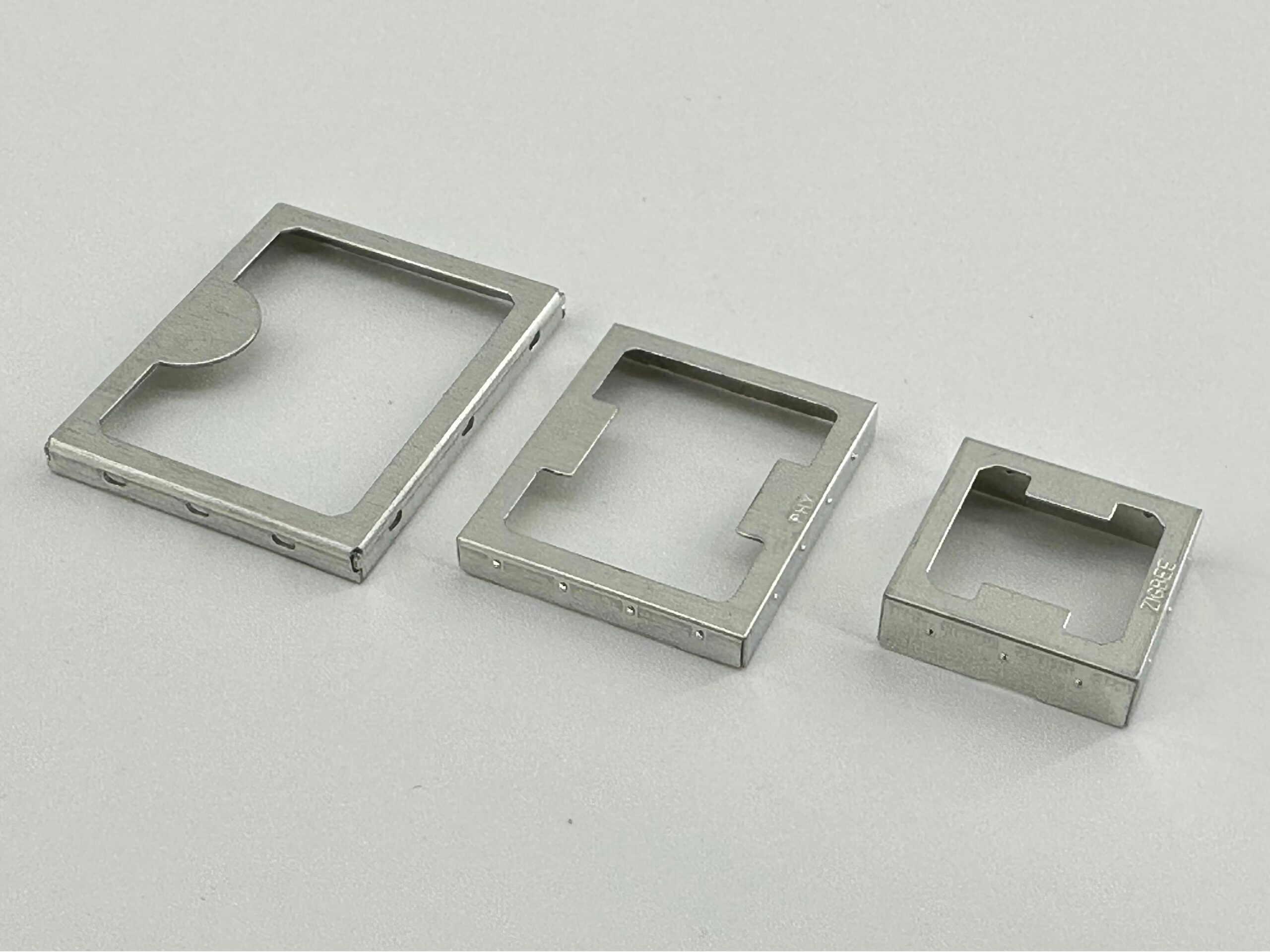

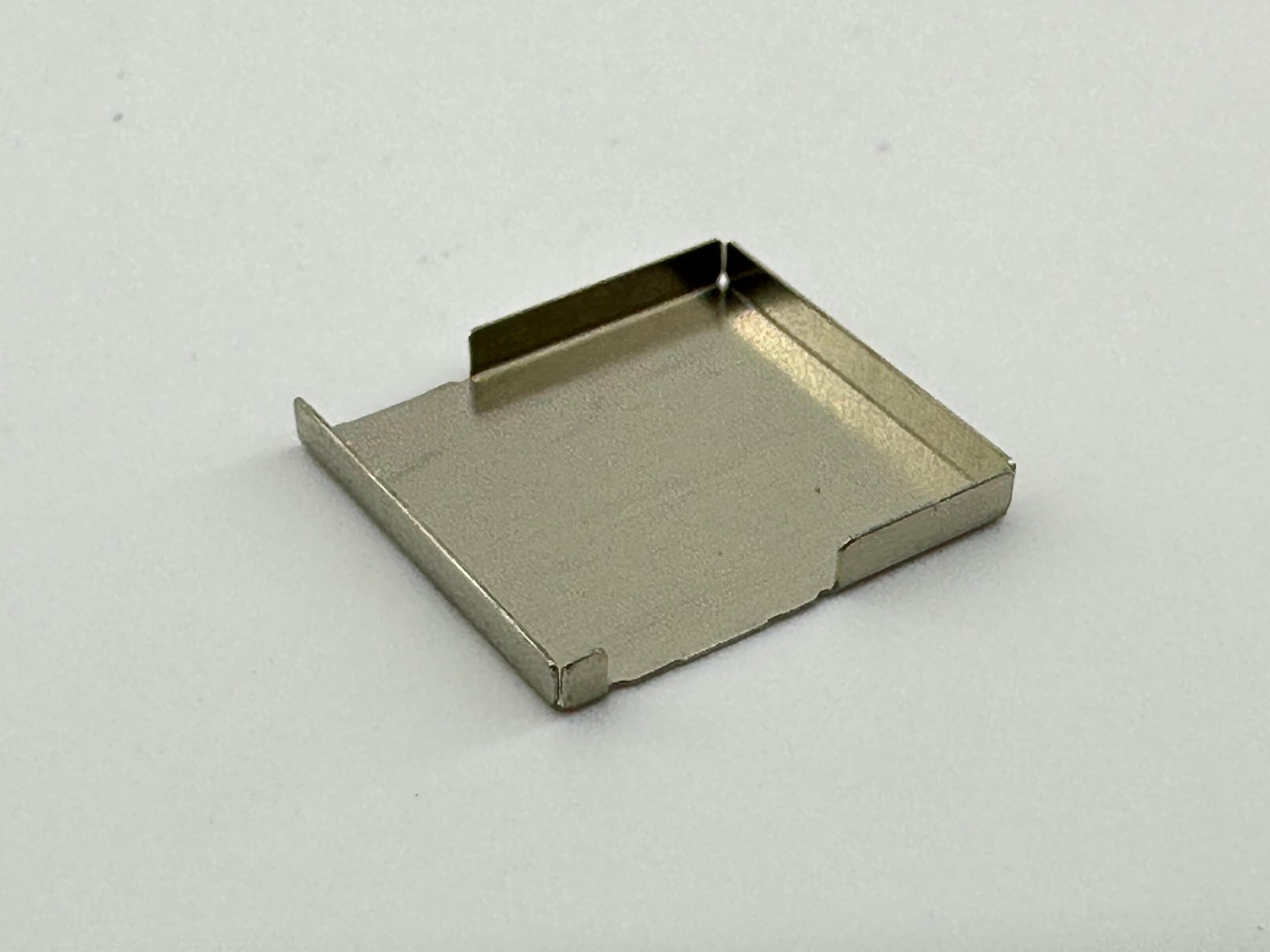

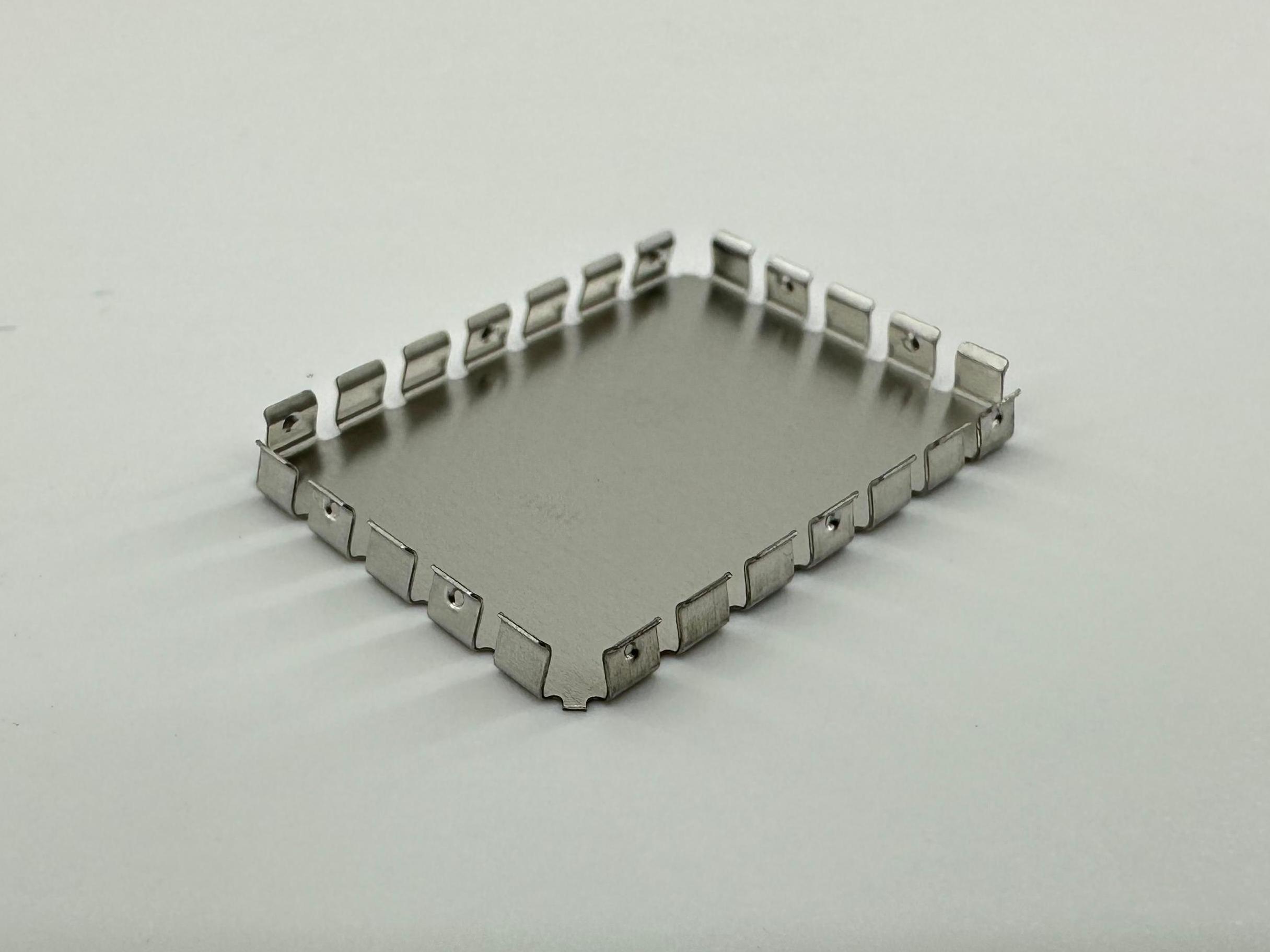

EMI Shielding Solution

What is an Electromagnetic Shield?

An electromagnetic shield is a protective component used to protect sensitive electronic parts from exposure to external electromagnetic interference (EMI). It helps to minimize the intrusion of disruptive electromagnetic fields that could compromise signal clarity, accuracy, or device operation.

Electromagnetic shielding is crucial in maintaining electromagnetic compatibility (EMC), especially as modern electronic systems grow more compact and complex. It ensures stable performance and a prolonged device lifespan.

At Dingmetal, we specialize in designing and manufacturing high-performance EMI shielding solutions tailored to your unique needs. With extensive experience and advanced capabilities, we combine precision and cost-effectiveness into our shields, empowering your products to stay reliable and compliant in today’s interference-prone environments.

How Does EMI Shielding Work?

EMI shielding works by creating a physical barrier. They are typically made of conductive materials, such as aluminum, copper, or specialized coatings, to block or attenuate unwanted electromagnetic waves. By reflecting or absorbing incoming signals, shields prevent them from reaching sensitive electronic components and causing potential disruption.

While EMI shields may not eliminate all interference, they significantly reduce the amplitude of electromagnetic waves, much like how noise-canceling headphones lower the loudness of sound. By wakening the strength of the interference, they help maintain signal integrity and device performance. Their effectiveness depends on several factors, including material conductivity, thickness, shield design, and the frequency of the interfering signals.

Why Choose Electromagnetic Shielding Solutions from Dingmetal

- Premium Materials

Dingmetal utilizes high-quality materials known for their excellent conductivity and absorption properties, including copper, aluminum, and specialized conductive alloys, to produce EMI shielding components. Our shields are crafted from continuous, structurally strong metals that ensure durability and integrity even in challenging operational conditions.

- Reliable Shielding Performance

Backed by advanced precision stamping processes, our electromagnetic shielding products deliver consistent performance across a wide frequency range. Our solutions effectively block external interference, minimize signal degradation, and maintain the stability of sensitive components, resulting in improved system longevity and functional safety.

- Cost-Effective Engineering

With rich industry experience and proactive engineering support, we help customers tackle EMI challenges with practical, cost-efficient shielding strategies. Thanks to optimized designs and manufacturing approaches, our EM shields not only support regulatory compliance and product reliability but also reduce overall costs.

Applications of Our EMI Shields

Discover our high-performance EMI shielding solutions, expertly crafted to safeguard your electronics from electromagnetic interference. Our diverse shield products provide reliable protection for sensitive equipment across various industries, including telecommunications, aerospace, and consumer electronics. Trust Dingmetal to deliver the optimal shielding solution for your needs, ensuring the longevity and performance of your devices.

FAQ on EMI Shielding

Q1: How do I choose the right electromagnetic shields?

Start with understanding your device’s specific requirements and operating environment. Key factors include the frequency range of the potential interference, the desired shielding effectiveness (typically measured in decibels), material compatibility, space limitations, and compliance with relevant industry regulations.

For example, applications in medical fields may require 60–80 dB of shielding, while military or aerospace systems may demand over 100 dB. Rather than defaulting to overengineering, it is advisable to consult with EMI shielding experts to tailor a solution that balances performance, material efficiency, and cost-effectiveness for your application.

Q2: Does my product require EMI shields?

You can determine whether your product needs EMI shielding by considering the following factors: whether it contains sensitive electronic components, operates in environments with strong electromagnetic fields, or must comply with EMC regulations. If so, shielding is likely essential. Additionally, if your device could emit signals that interfere with nearby equipment, implementing shielding is crucial. It is also advisable to conduct early-stage EMI testing during the prototyping phase, which helps identify vulnerabilities and prevents costly modifications later on, ensuring performance reliability and compliance with regulations.

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap