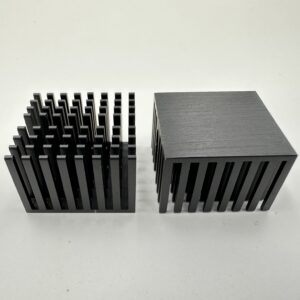

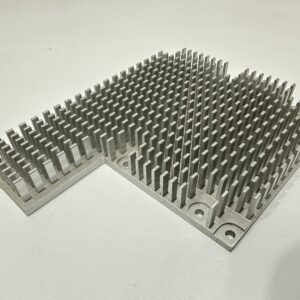

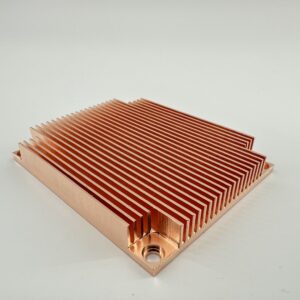

What is a Heat Sink?

A heat sink is a critical component in electronic devices used to dissipate heat and prevent overheating. Made primarily from metals like aluminum or copper, heat sinks function by increasing the surface area to facilitate heat transfer. Through fins or other structures, they enhance airflow or other cooling mediums, ensuring devices stay at safe temperatures and preventing damage from excessive heat.At Dingmetal, we have accumulated extensive experience in heat sink manufacturing, offering a wide range of custom heat sinks designed to meet the specific cooling requirements of your applications. Explore our collections and request a quote for a tailored solution!

Why Choose Dingmetal as Your Heat Sink Supplier

Dingmetal has specialized in heat sink manufacturing for over 10 years, offering an extensive range of options to meet the diverse needs of various industries. Our selection includes BGA heat sinks, cold-forged heat sinks, die-casting heat sinks, extrusion heat sinks, heat pipe heat sinks, machined heat sinks, and skived heat sinks. No matter the application, we have the right solution to ensure optimal thermal performance for your devices.

- Highly Customizable Options

With over 90% of our products being custom-made, we take pride in our ability to provide tailored solutions for specific requirements. Thanks to our superior manufacturing capabilities, we can produce highly customized heat sinks that match your exact needs, Whether adjusting the design, material, or size.

- Low MOQ for Flexible Ordering

At Dingmetal, we cater to a wide range of order sizes with a low minimum order quantity. For standard heat sinks, the MOQ starts at just 10 pieces, while for custom heat sinks, the MOQ begins at 50 pieces. With enhanced flexibility, we can accommodate businesses of all sizes, allowing you to order precisely what you need, whether for small-scale prototypes or large production runs.

How to Work with Us for Custom Heat Sinks

- Design and Discussion of Solutions

We start by discussing your specific requirements and exploring design options for your custom heat sinks to meet your thermal and mechanical needs.

- Quotation

After finalizing the design, we provide a detailed quotation that includes pricing and lead times, ensuring complete transparency to help you make informed decisions.

- Sample Production

Upon confirming the quotation, we will send a sample for your approval, allowing you to assess the performance and quality.

- Customer Approval

Once you approve the sample, we will make any final adjustments if needed and then prepare for mass manufacturing of the heat sinks.

- Official Molding

Upon sample approval, we enter the official molding process to create the custom heat sinks for large-scale production, ensuring consistency and precision in every unit produced.

- Mass Production

Once the molds are finalized, we move to mass production. Our team maintains high standards and ensures on-time delivery for your order.

FAQs on Heat Sink Manufacturing

- Q1: What is the MOQ for standard and custom heat sinks?

A1: For standard heat sinks in stock, we offer a minimum order quantity of 10 pieces. For custom heat sinks, the MOQ typically starts at 50 pieces, depending on the complexity and specifications.

- Q2: What is the payment method for heat sink manufacturing?

A2: For the initial order, we require 100% payment via T/T before shipment. For subsequent orders, we can accommodate payment terms based on an agreed-upon credit period, offering flexibility to meet your business needs.

- Q3: Is heat sink assembly service available at Dingmetal?

A3: Yes. As a heat sink supplier with years of experience, we provide assembly services tailored to your requirements. We work closely with clients to ensure that the assembly process aligns with specific needs, delivering a fully integrated solution.