- Sorry, this product cannot be purchased.

Products

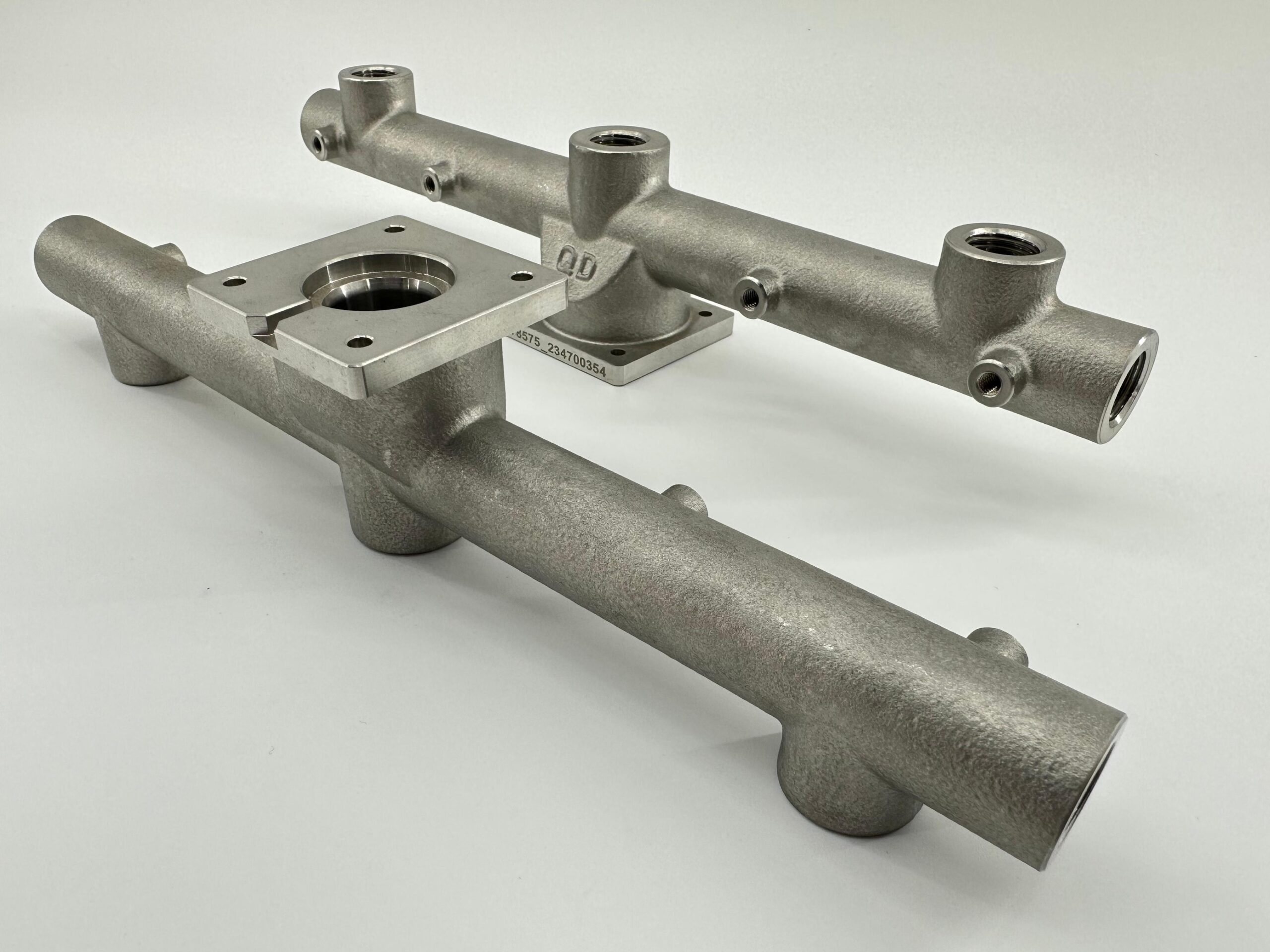

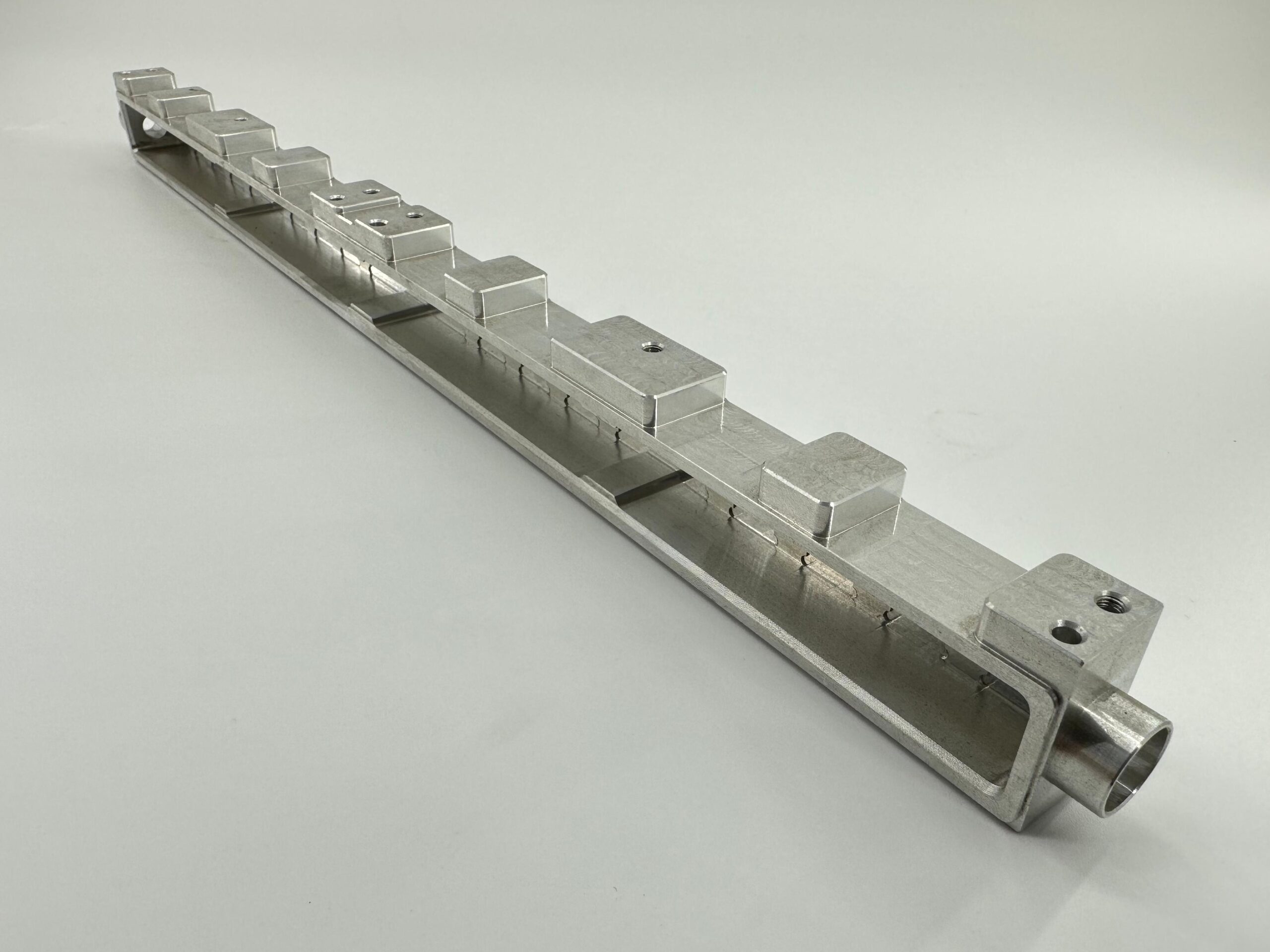

Manifold

What is a Liquid Cooling Manifold?

A manifold is essential in liquid cooling systems. It can centralize fluid connections and distribute coolant efficiently across different pathways. By directing flow with precision, it helps maintain stable operating temperatures, reduce the risk of leaks, and simplify system installation and maintenance.

At Dingmetal, we offer a range of liquid cooling manifolds, including intake and exhaust manifolds, as well as fuel rail types tailored to meet various system requirements.

Types of Liquid Cooling Manifold

Liquid cooling manifolds come in two main types depending on their function, structure, and application. Contact us to find the right solution customized to meet your needs!

They can evenly supply coolant from a main line to multiple branches to prevent hotspots and maintain consistent temperatures. As a specialized form, the coolant distribution manifold is commonly used in electric vehicle battery packs and data center liquid cooling, featuring customizable outlets, sensors, or control valves for optimized flow management.

Gathering coolant from multiple return lines into a single outlet, these components simplify system layout for smooth return flow. By combining distribution and collection functions in a single unit, integrated manifolds optimize space and reduce piping complexity.

Manifolds can vary in structure, including linear, modular, plate/block, or loop configurations. They may be passive or active, with integrated valves and sensors to provide precise control.

Key Features of Industrial Manifolds

Superior Cooling Performance

Liquid manifolds provide precise control over coolant delivery, ensuring each component receives the exact amount of cooling required. Thanks to their targeted cooling capability, they can safeguard sensitive hardware, enabling the system to handle higher workloads without overheating risks.

Improved Energy Efficiency

By optimizing flow paths and pressure distribution, industrial manifolds enhance fluid dynamics within cooling systems. Therefore, they lead to less energy consumption and higher power efficiency, resulting in more sustainable and cost-effective operations. Additionally, Reducing energy waste supports long-term operational efficiency.

Enhanced Thermal Stability

Liquid cooling manifolds ensure consistent and balanced coolant distribution, leading to reduced thermal fluctuations. They help minimize mechanical stress on components, enhancing overall system reliability and longevity. With fewer temperature spikes, manifolds lower the risk of failures and downtime.

Why Choose Custom Liquid Manifolds

from Dingmetal?

- 5+ Years of Experience

With over five years of experience in liquid manifold manufacturing, Dingmetal combines deep process knowledge with strong in-house capabilities. From CNC machining of complex internal channels to die casting and precision tooling, we have integrated the entire production chain, delivering improved quality and faster lead times.

- Trusted by Global AI Manufacturers

We are a long-term secondary supplier for leading AI hardware brands, supporting consistent delivery of cooling modules under tight schedules. With stable production capacity and dependable quality, we become a trusted partner for demanding projects.

- Reliable and Consistent Quality

Each manifold withstands strict inspection using Coordinate Measuring Machines (CMM) and Keyence laser systems to ensure dimensional accuracy. We utilize dedicated testers to verify surface roughness and corrosion resistance, ensuring every unit performs reliably under pressure and long-term operation.

Applications of Our Liquid Cooling Manifolds

Our liquid cooling manifolds are applied in AI server cooling, aerospace thermal management, and medical equipment, where precise and reliable fluid distribution is crucial. Designed for compact and high-performance systems, they ensure stable, leak-free coolant flow to cold plates and other key components. Do not hesitate to shoot us your requirements—we are here to support your cooling needs.

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap