- Sorry, this product cannot be purchased.

Products

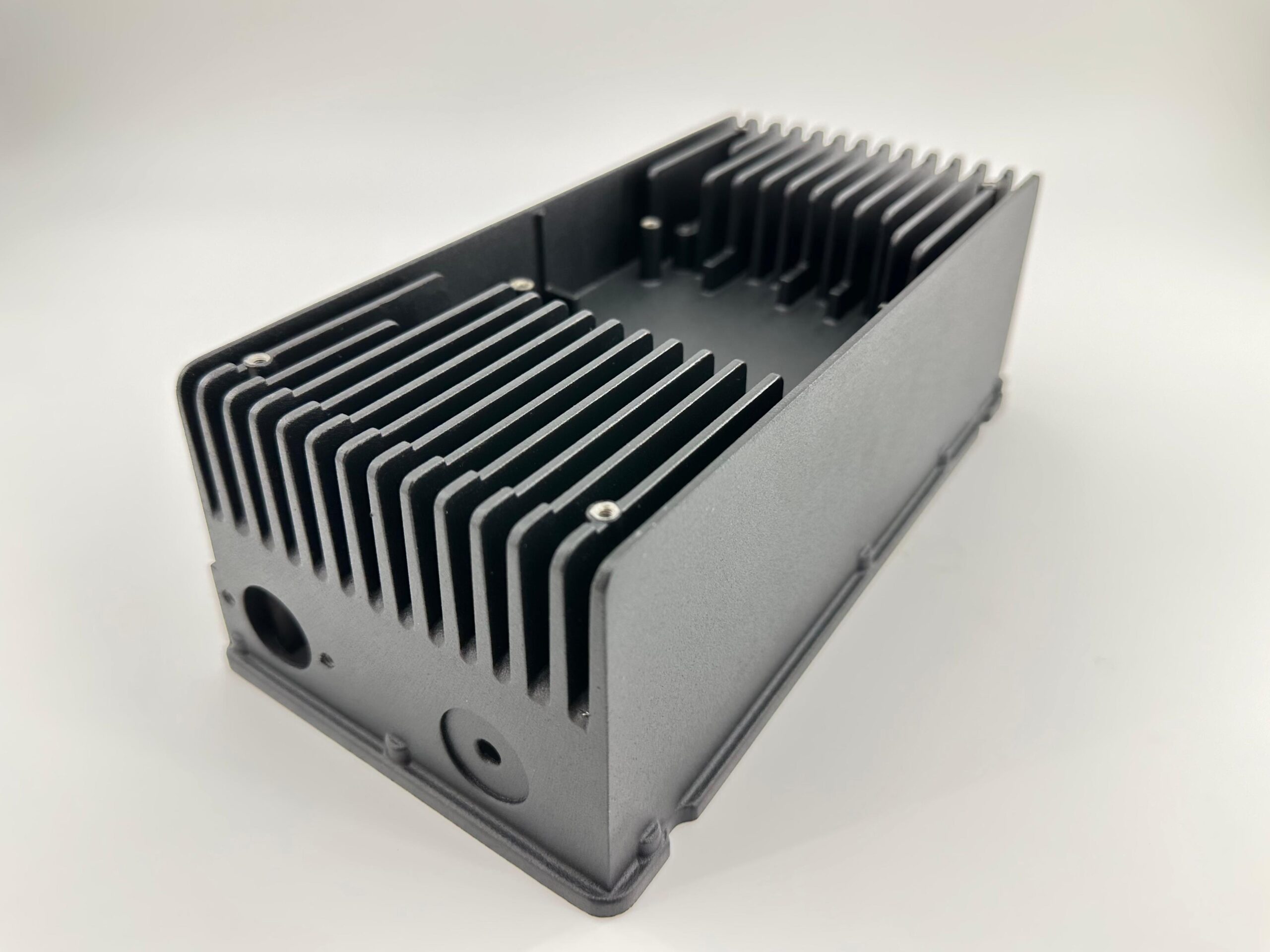

Die Casting

What is Die Casting?

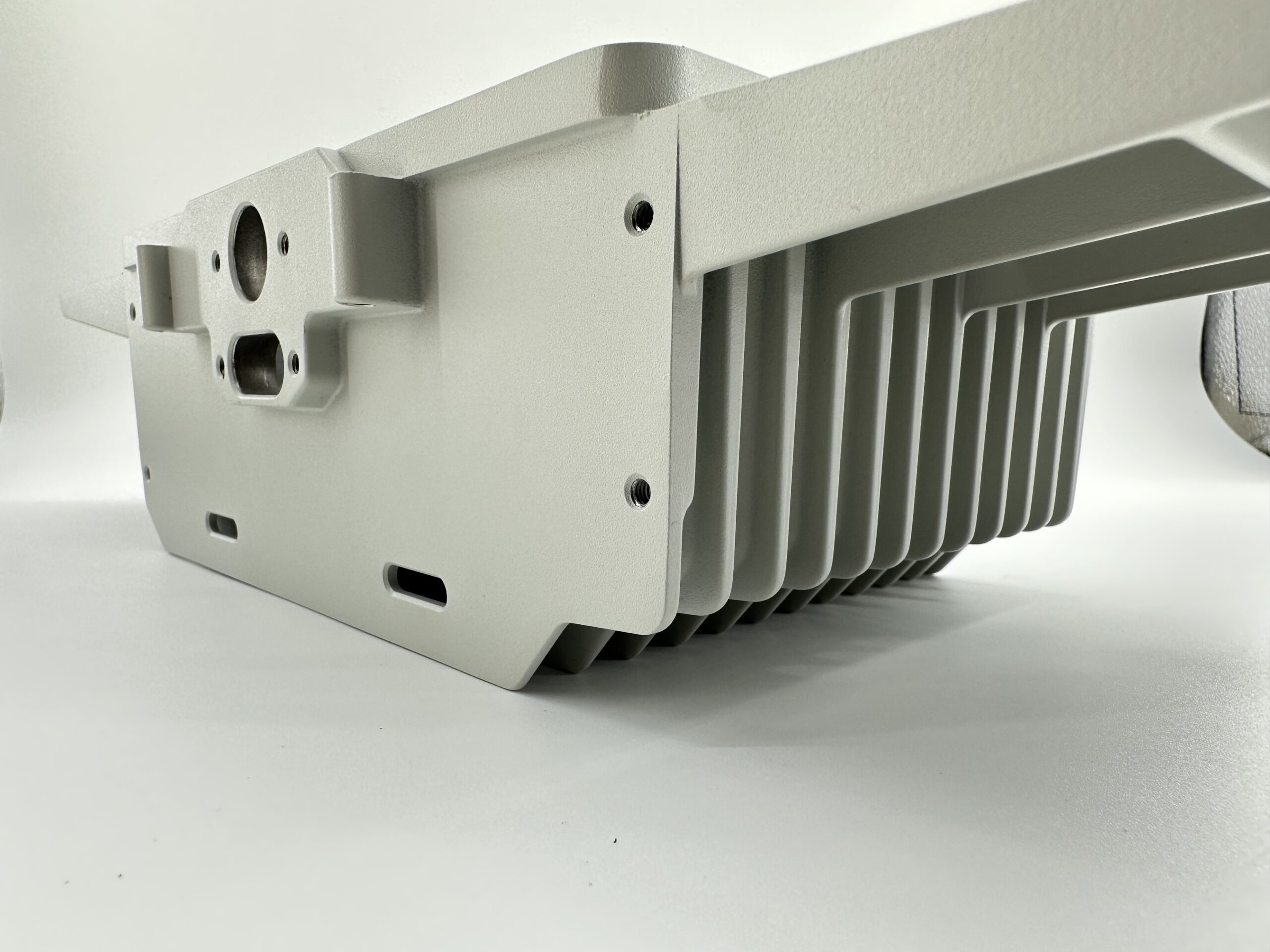

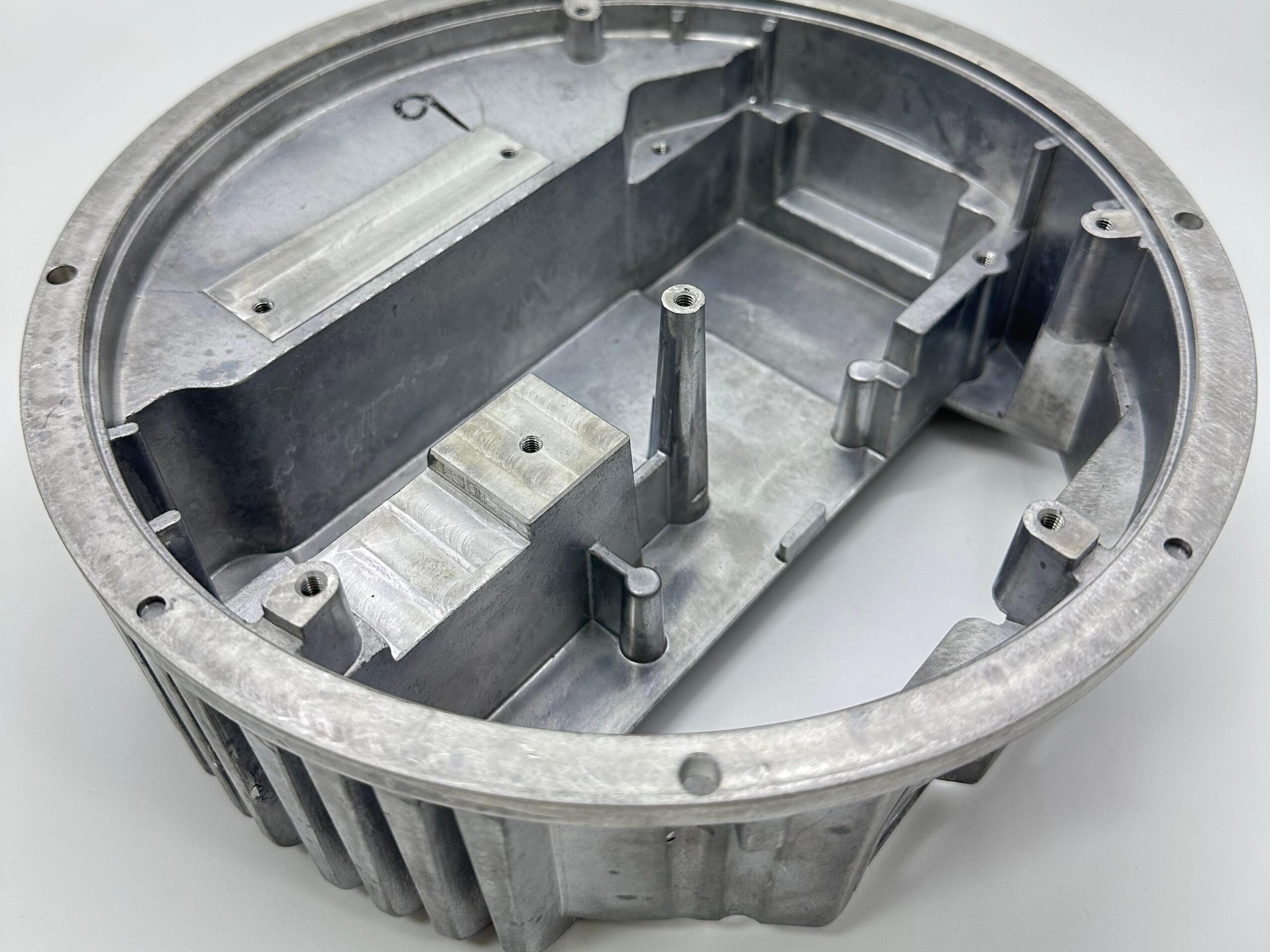

Die casting involves injecting metal into specialized molds, known as dies, under high pressure. It allows for the mass production of complex metal parts with exceptional dimensional accuracy, smooth surfaces, and consistent quality. It is particularly cost-effective for high-volume production runs, typically over 1,000 units, where reduced unit prices and shorter cycle times can offset the initial tooling and Non-Recurring Engineering (NRE) costs.

At Dingmetal, we specialize in OEM and ODM die casting services, delivering parts with intricate geometries and tight tolerances that are often difficult to achieve with other methods. With advanced manufacturing capabilities, we ensure many components require minimal post-processing or machining, saving time and cost while accelerating your path to business success.

Our Die Casting Process

At Dingmetal, we specialize in cold chamber die casting, offering reliable solutions for high-melting-point metals. This method uses an external furnace to melt the metal.

It involves manually pouring molten material into a cold shot chamber first and then injecting it into the mold under high pressure. This technique delivers excellent dimensional accuracy, strong mechanical properties, and longer equipment life, making it ideal for producing durable and structurally strong die casting parts with complex geometries.

Available Materials

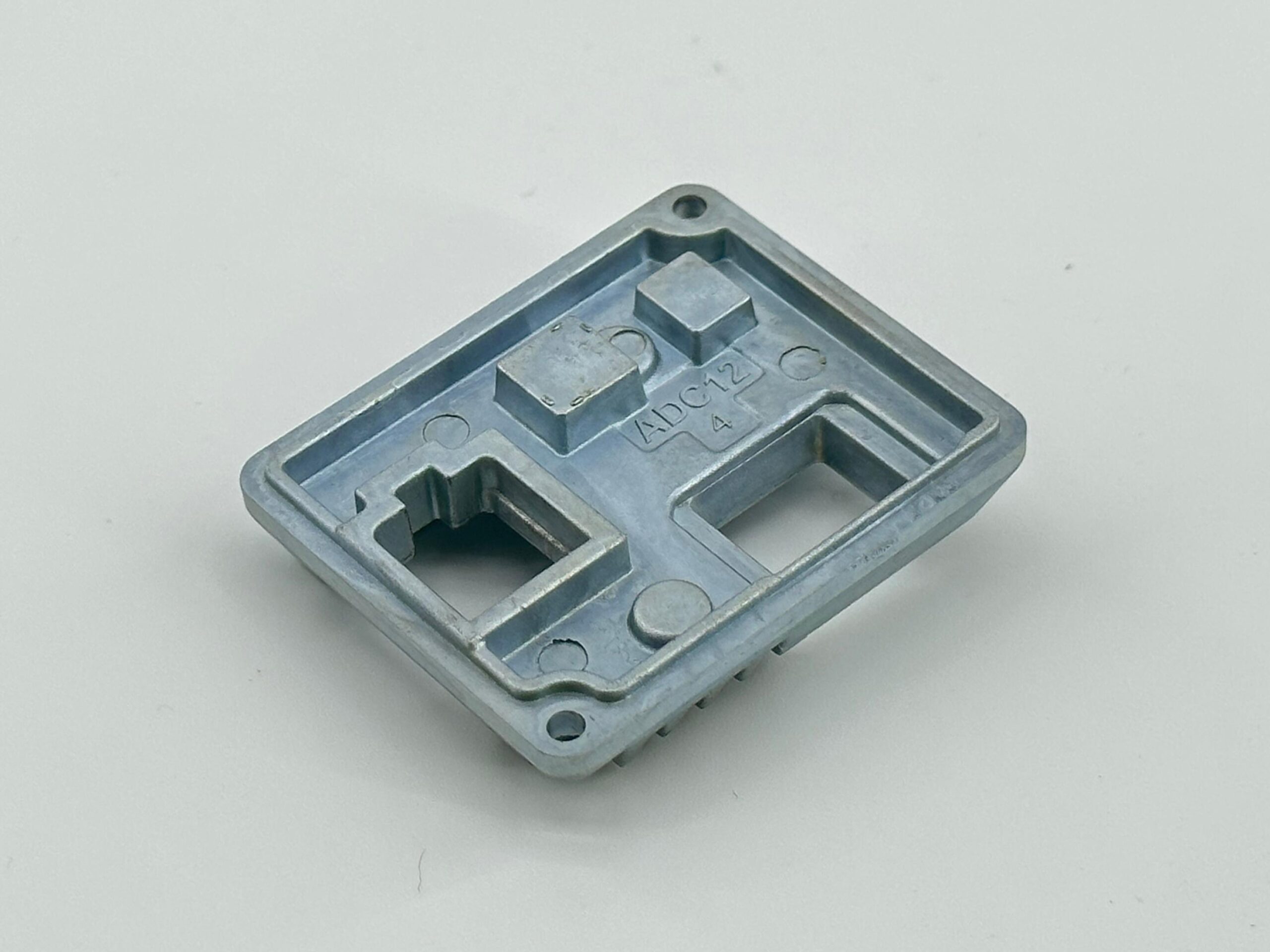

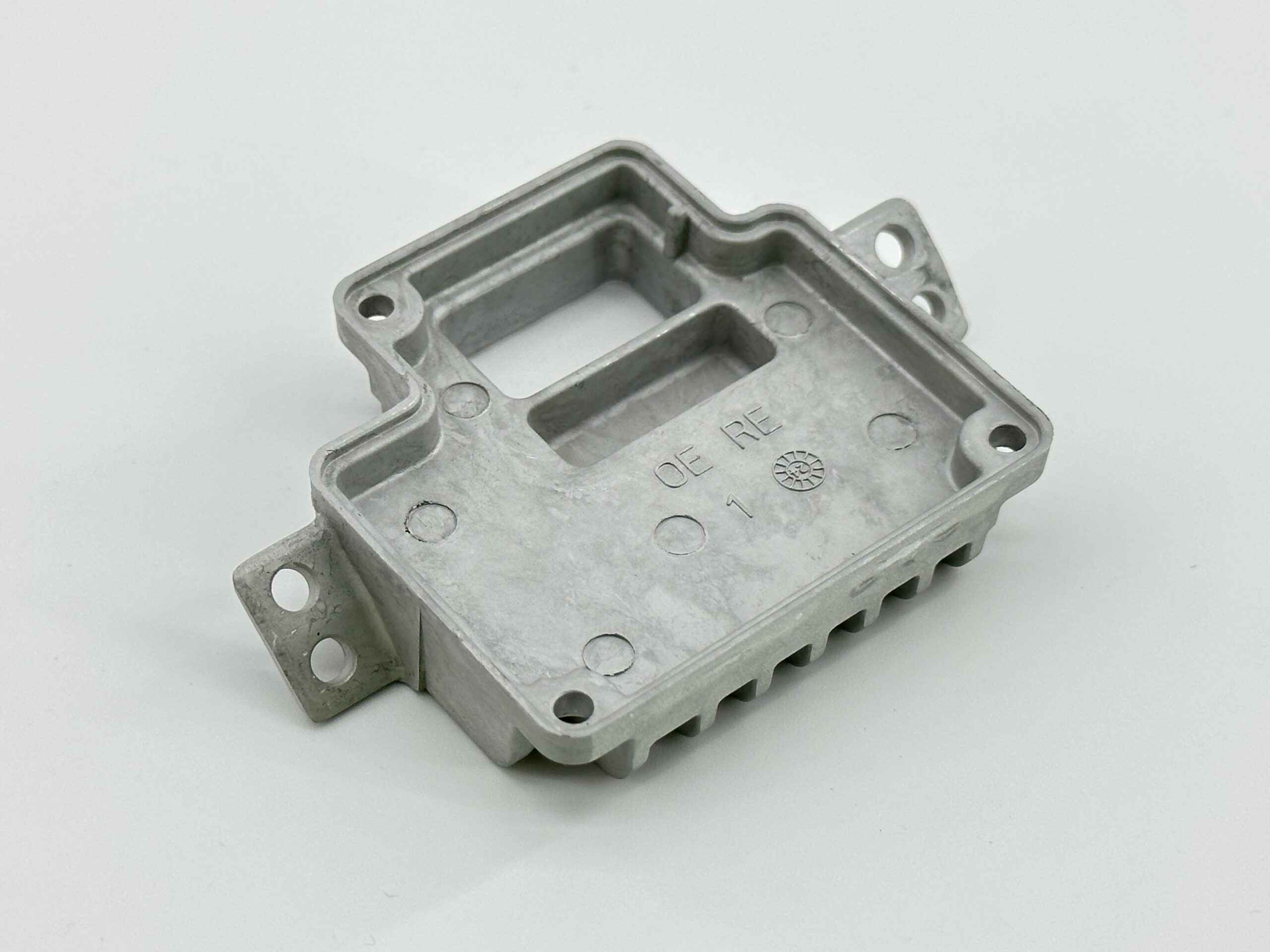

Dingmetal offers various material options to suit application needs. Selecting the appropriate material is crucial to ensure performance, durability, and cost-effectiveness in precision turning parts.

Preferred for high-precision, high-tolerance components with excellent durability and castability.

The lightest structural metal, known for its strength-to-weight ratio, perfect for electronic and automotive applications.

Lightweight, corrosion-resistant, and ideal for aerospace and automotive parts where strength and minimal weight are equally important.

Surface Finishing Options

As Cast

Functional finish with minimal post-processing, suitable for internal parts.

Polishing

Bright, reflective surfaces with reduced roughness, ideal for visual or decorative applications.

Sand Blasting

Consistent matte texture removes minor defects and prepares parts for coating or painting.

Anodizing

Improved resistance to corrosion and wear, available in various colors, primarily used for aluminum parts.

Powder Coating

Thick, durable, and colorful protective layers. Resistant to chipping and corrosion.

Plating

Adds a thin layer of metal (such as nickel or chrome) on the dicasting parts to enhance corrosion resistance, electrical conductivity, or surface appearance.

Chemical Film

Forms a protective layer on aluminum surfaces, improving corrosion resistance while maintaining conductivity. Ideal for electronic and aerospace applications.

Custom

We also manufacture die casting parts with custom finishes tailored to your application needs.

Why Choose Dingmetal as Your

Die Casting Manufacturer

- Custom Manufacturing Expertise

At Dingmetal, we specialize in providing fully customized die-casting solutions tailored to your unique project needs. From intricate part designs to surface finishing, our team is experienced in delivering parts with complex shapes, tight tolerances, and consistent quality, helping you reduce post-processing and speed up product launch.

- Certified Quality Standards

We operate under strict quality systems, including ISO 9001:2015, ISO 14001:2015, and IATF 16949. These certifications reflect our commitment to high standards in product performance and environmental responsibility.

- Fast Turnaround Time

We understand the importance of efficiency and speed in competitive industries. That is why we offer prototype samples within 7–10 days and support mass production within 20–30 days. Our efficient process ensures timely delivery without compromising quality.

Applications of Our Die Casting Parts

Our die casting parts are widely used in automotive control units, industrial automation housings, power supply enclosures, and more. From motor housings to LED driver casings, we deliver precision and durability for high-performance environments. Explore our real-world cases and request your custom quote today!

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap