- Sorry, this product cannot be purchased.

Products

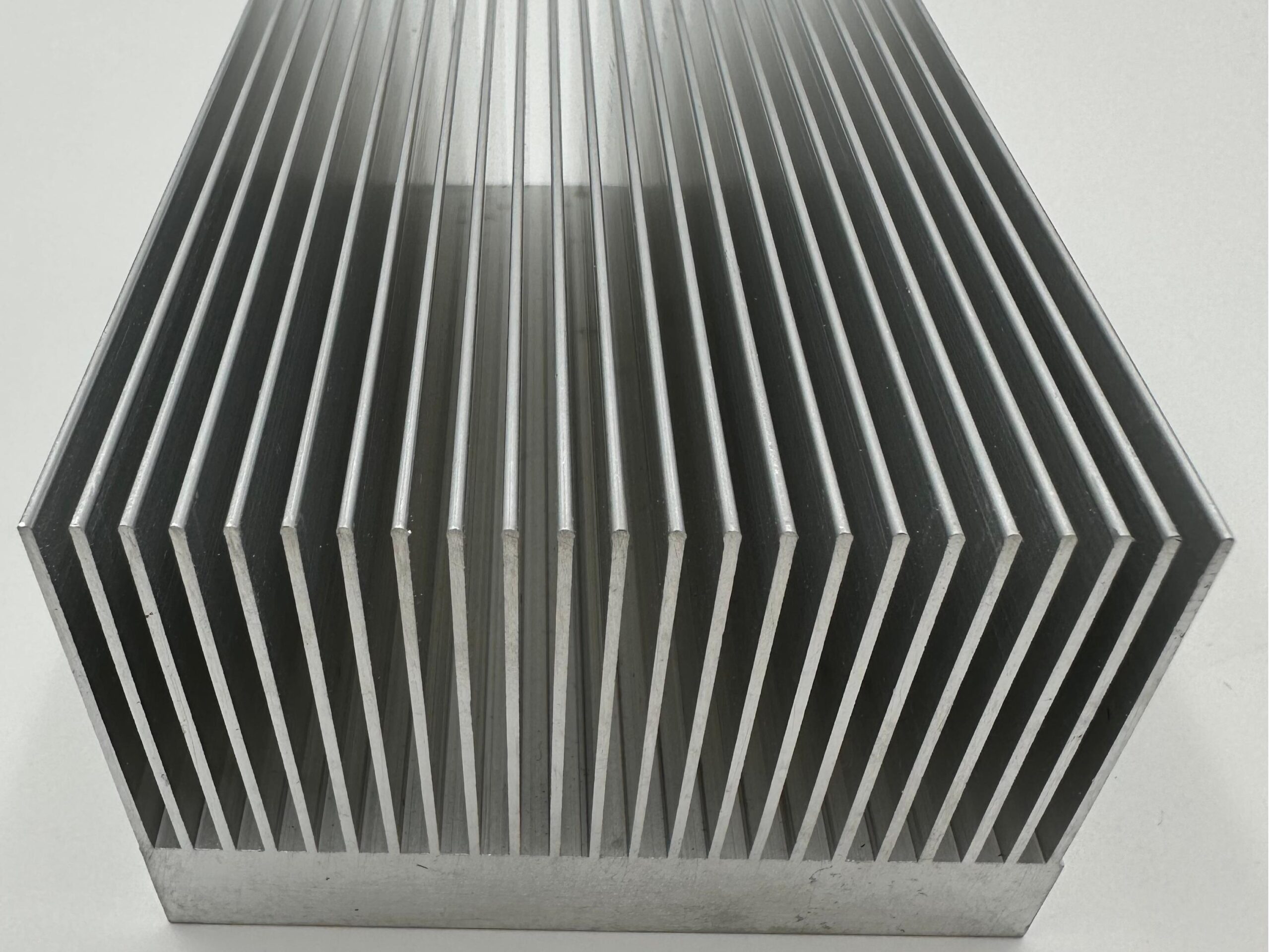

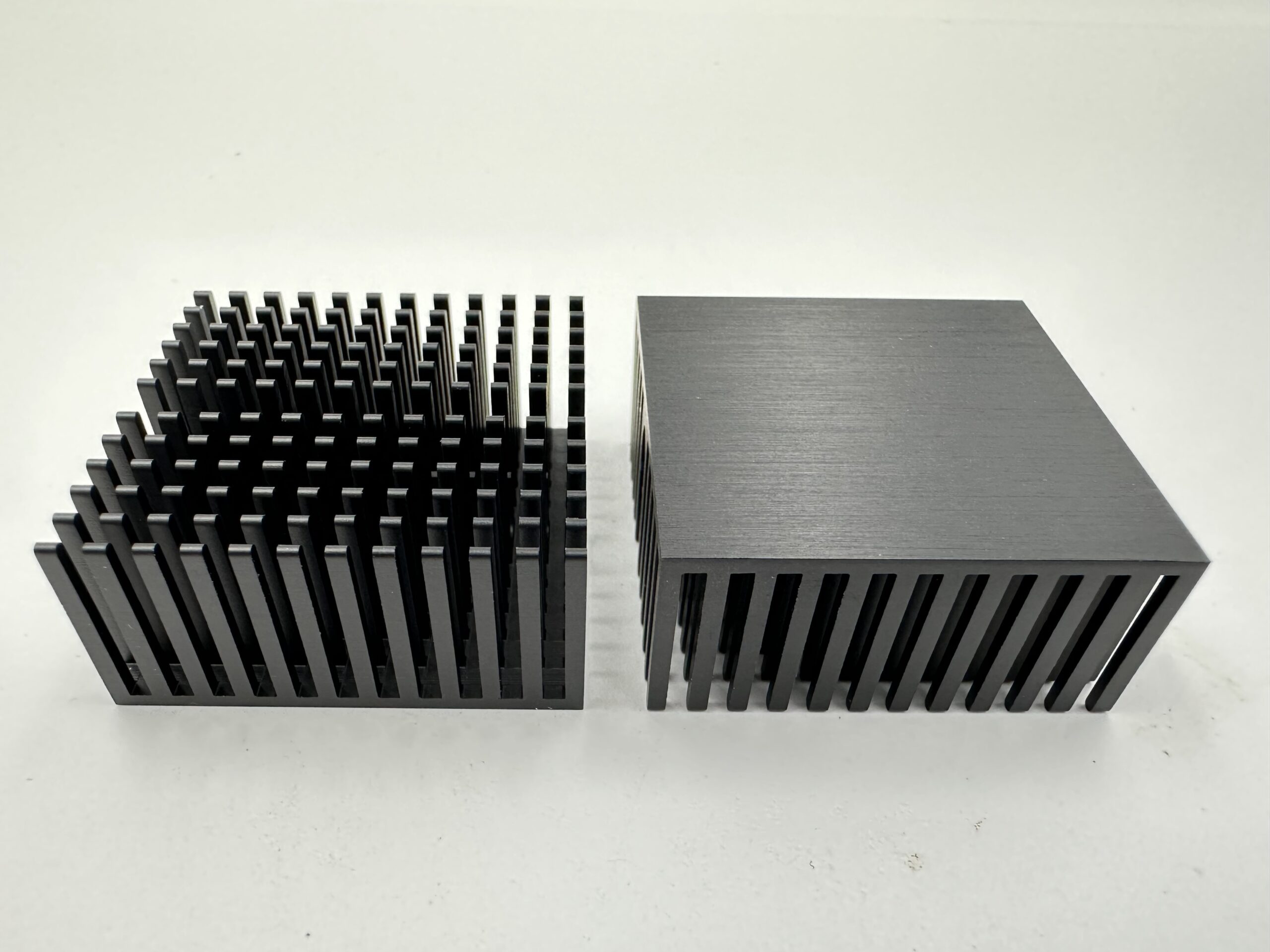

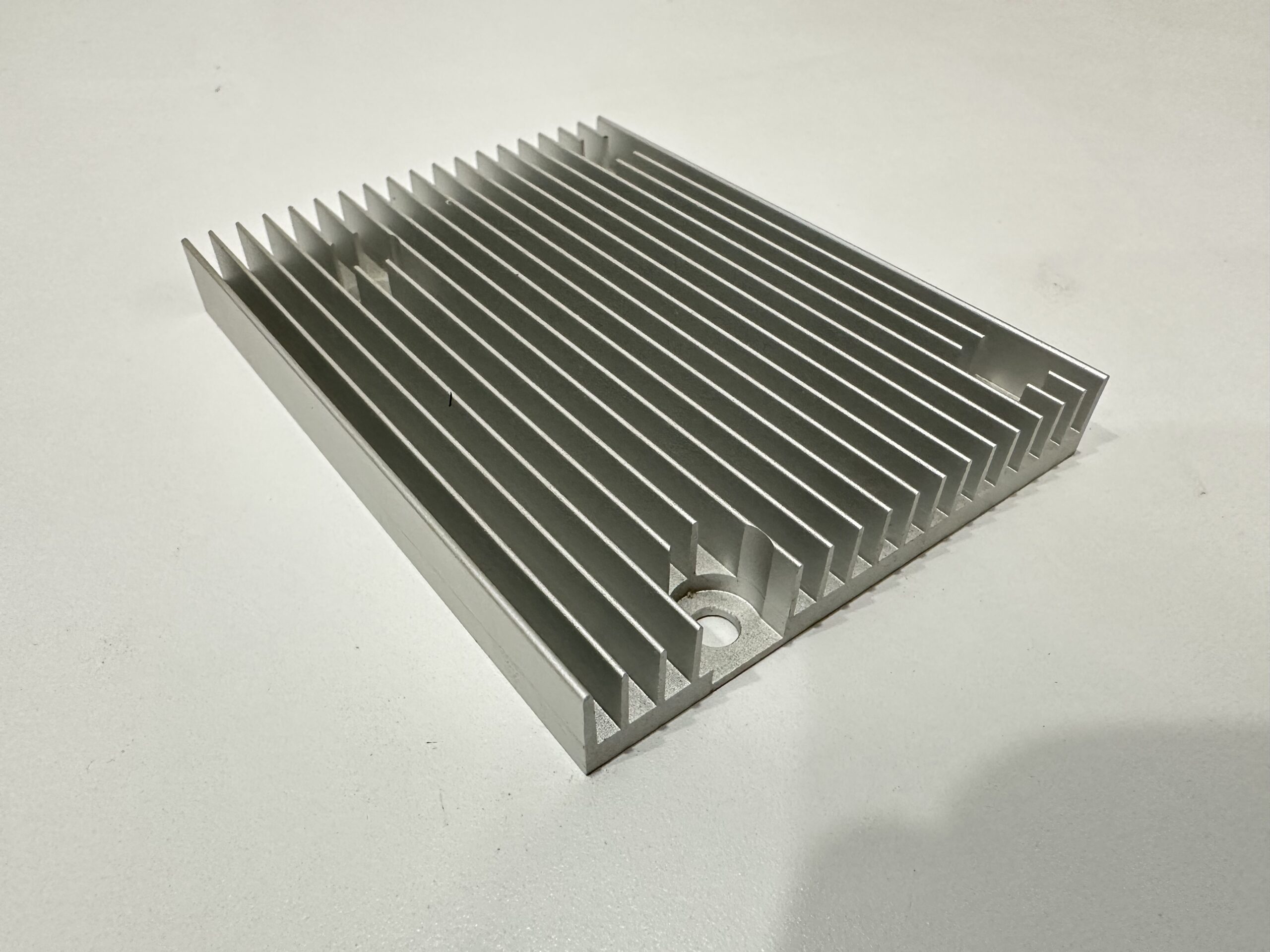

Extrusion Heat Sink

What is an Extruded Heat Sink?

An extruded heat sink is created through an extrusion process. It involves forcing heated metal, typically aluminum, through a die to create continuous profiles with specific cross-sectional shapes. With this method, heat sinks are produced with well-defined fin structures, thus delivering excellent thermal conductivity.

Materials & Surface Finishes

Extrusion heat sinks combine high thermal performance with versatile material and surface finish options, ensuring reliable cooling solutions for a wide range of electronic and industrial applications.

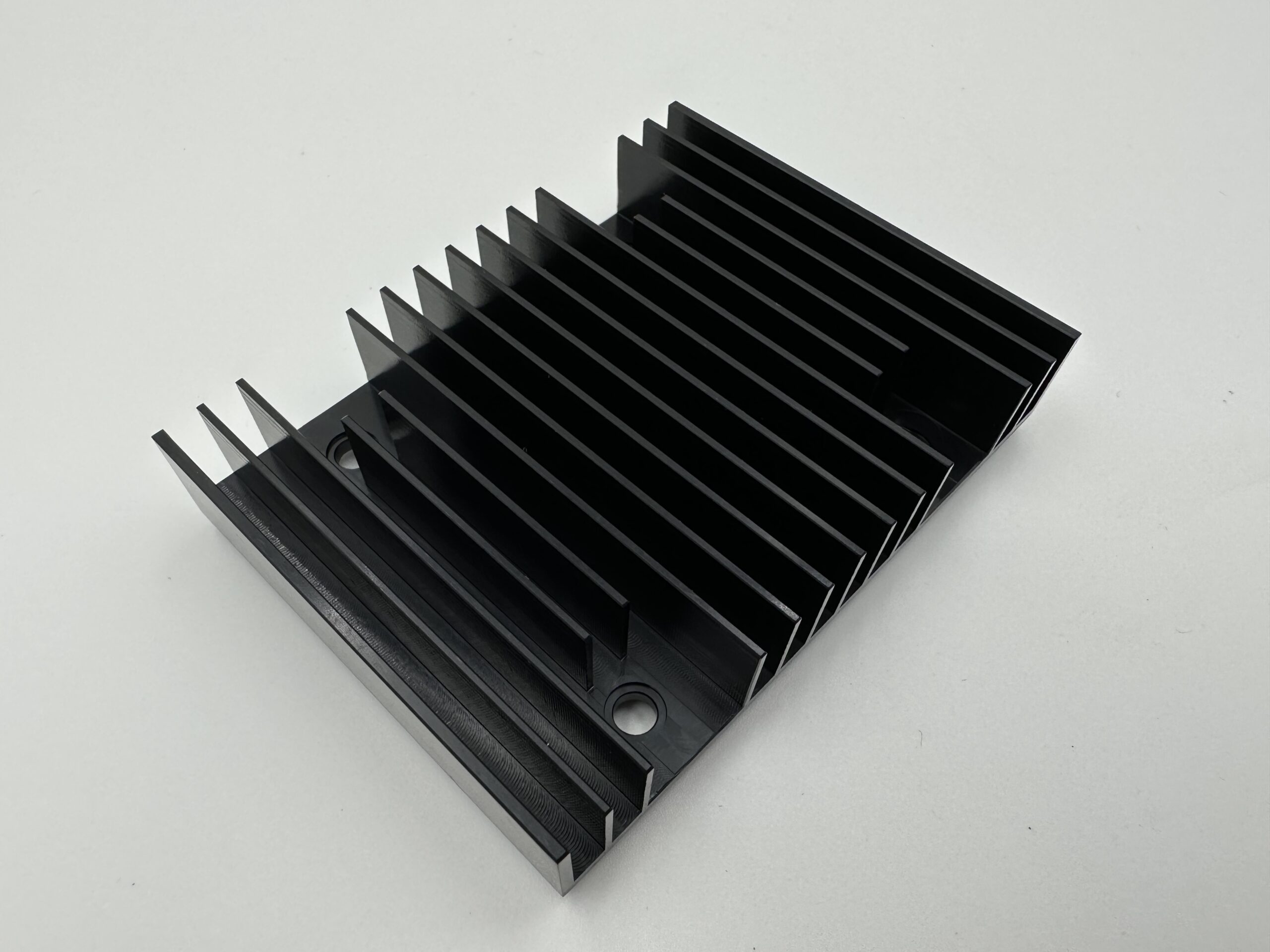

Extruded heat sinks are commonly made from aluminum alloys such as AL6063, due to their exceptional thermal conductivity, lightweight properties, and ease of machining.

Anodizing is often applied as a surface treatment to enhance corrosion resistance and surface durability. This process also improves the aesthetic appeal, providing a uniform finish for functional and visible components.

Benefits of Extrusion Heat Sinks

Cost-Effective for Mass Production

Extrusion heat sinks are recognized as an economical solution, particularly suitable for high-volume production. It keeps continuous profiles with minimal material waste in production, lowering costs while maintaining consistent quality.

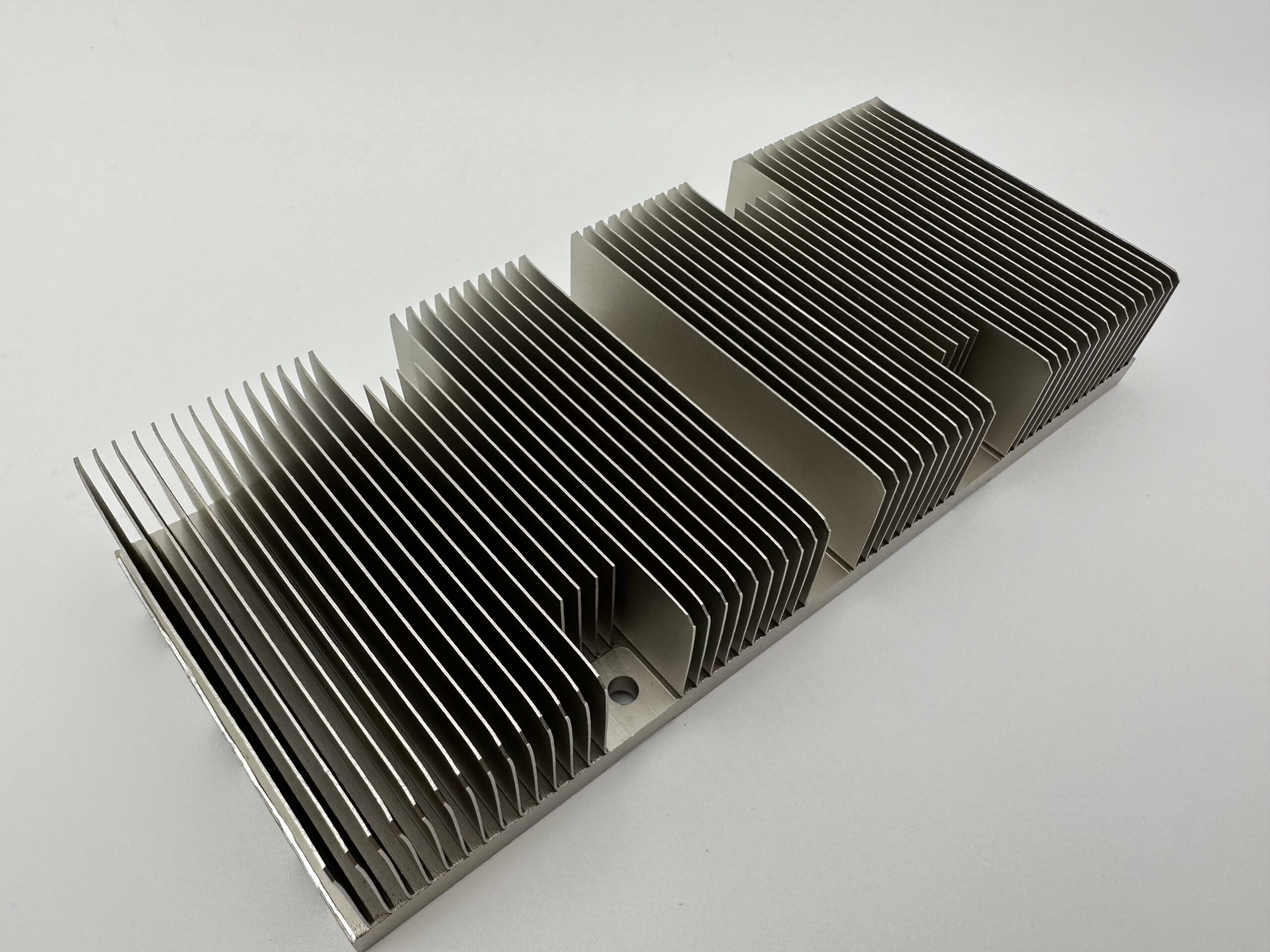

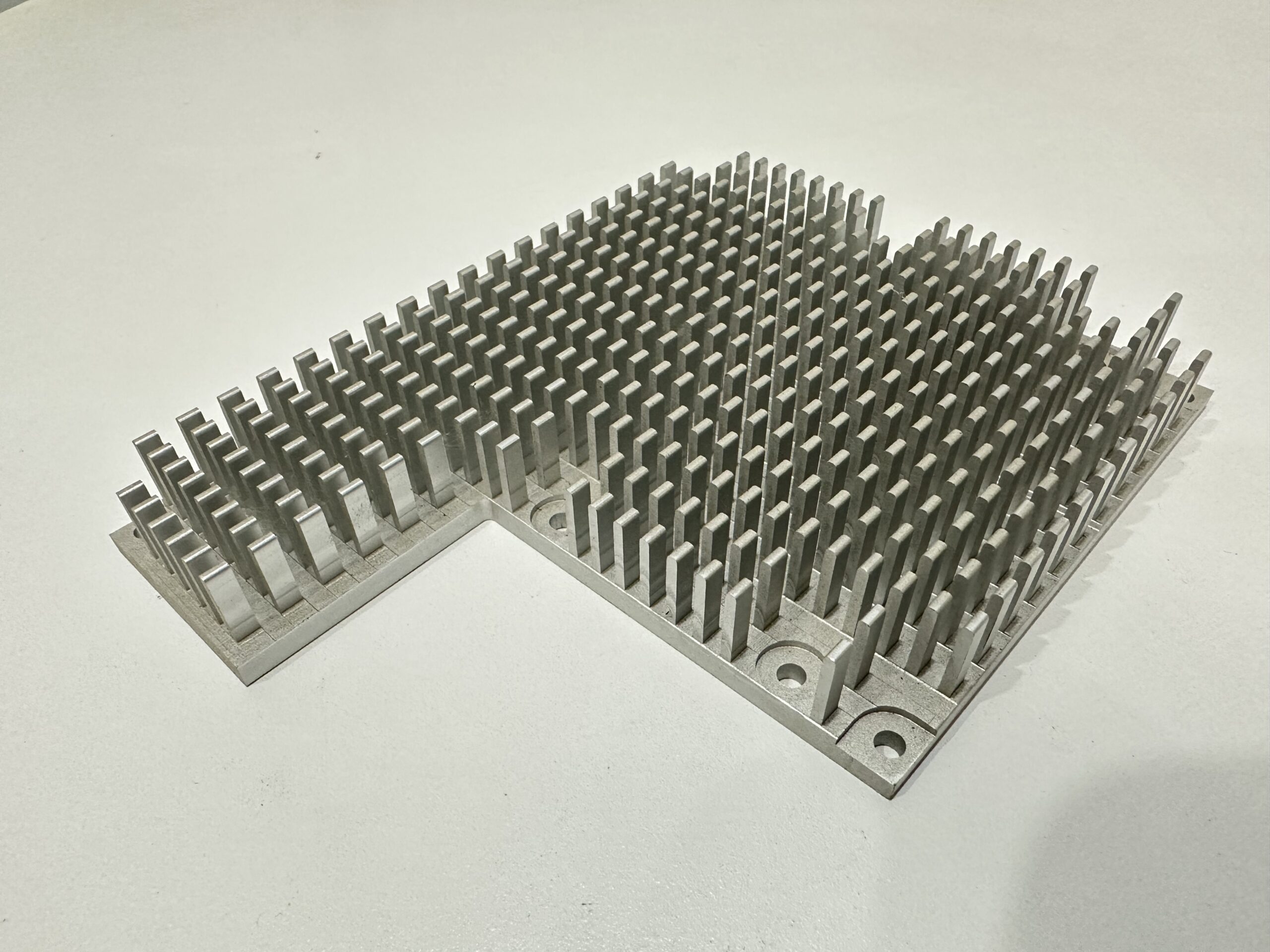

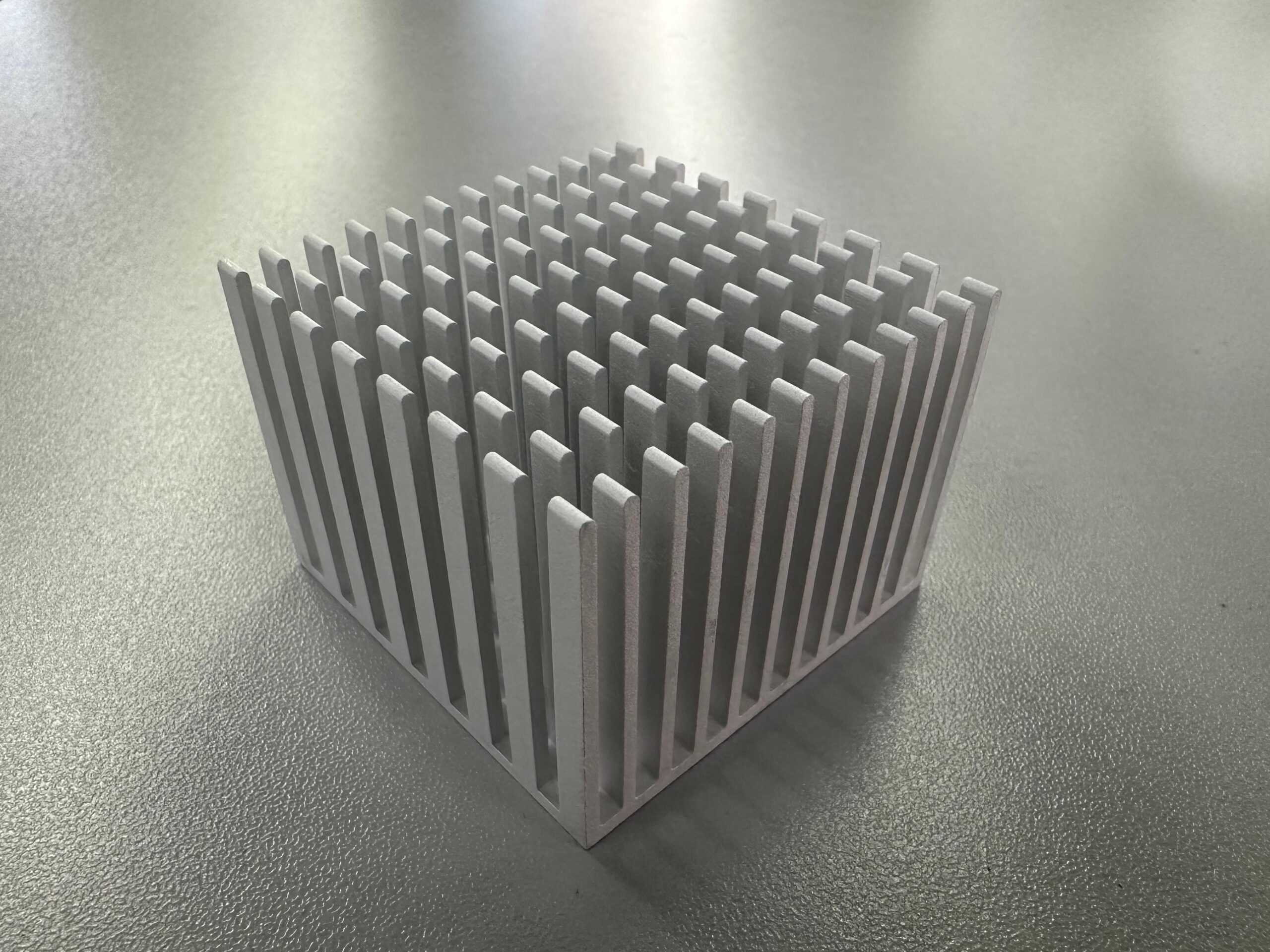

Flexible Profile and Design Options

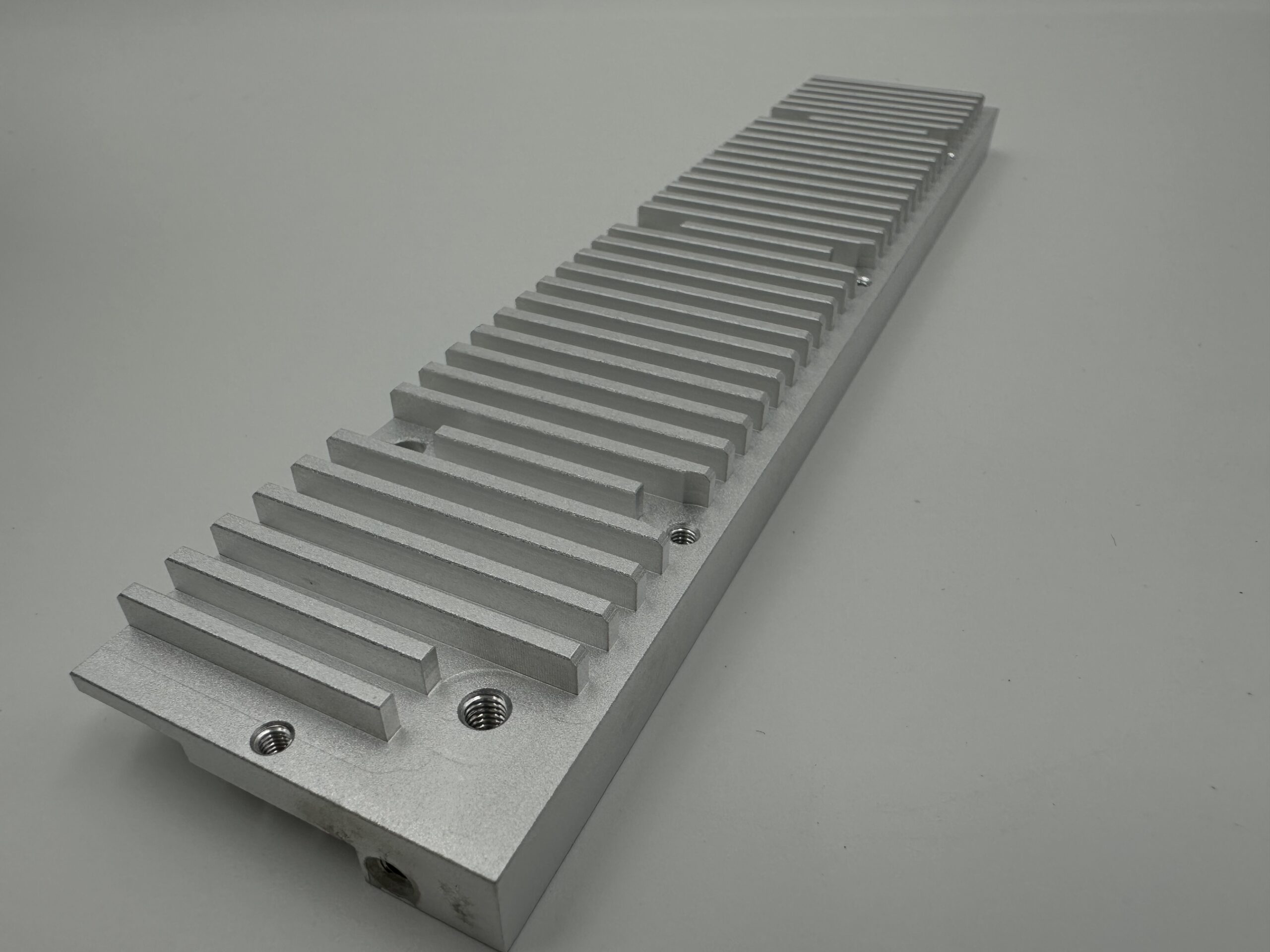

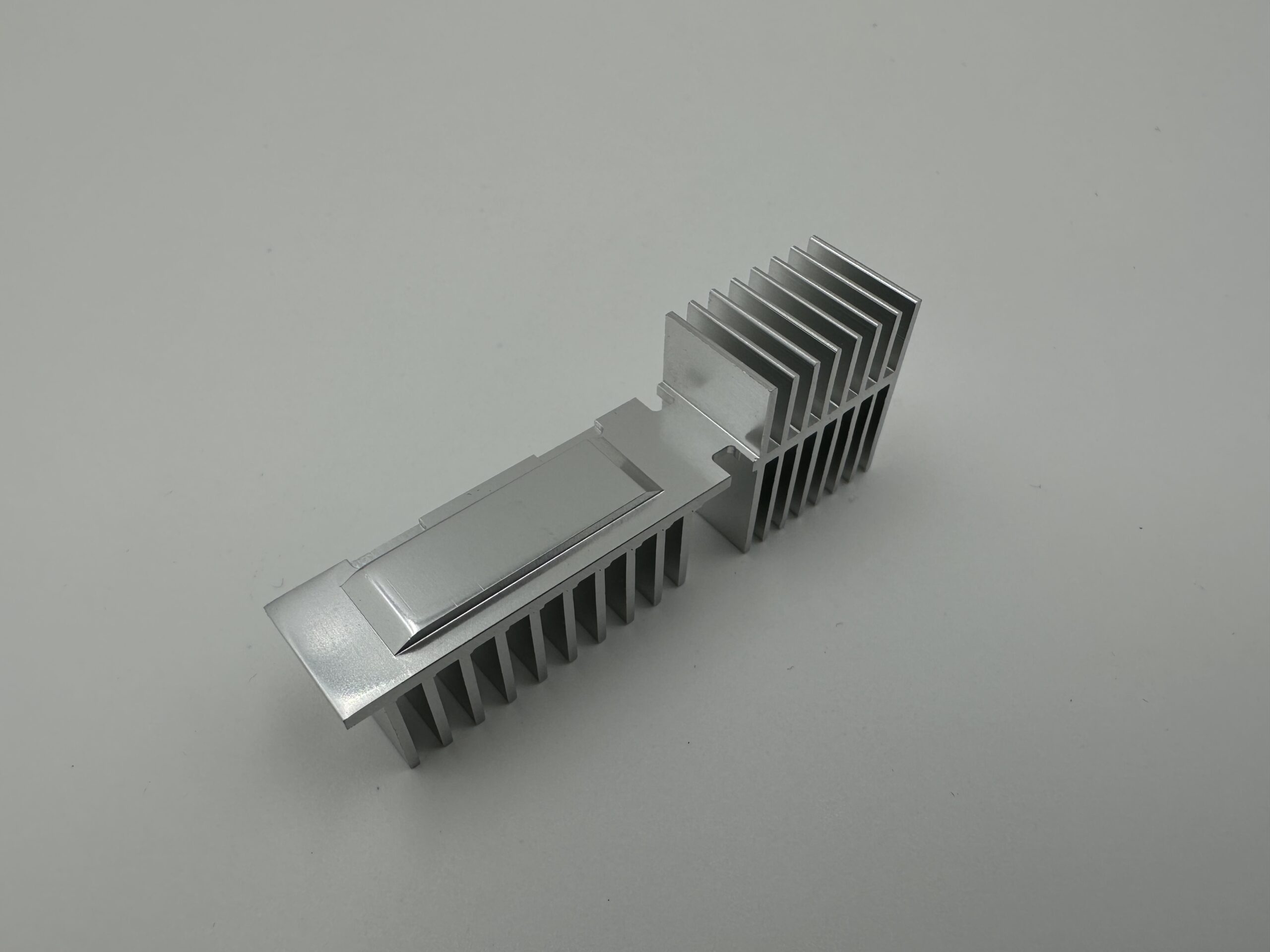

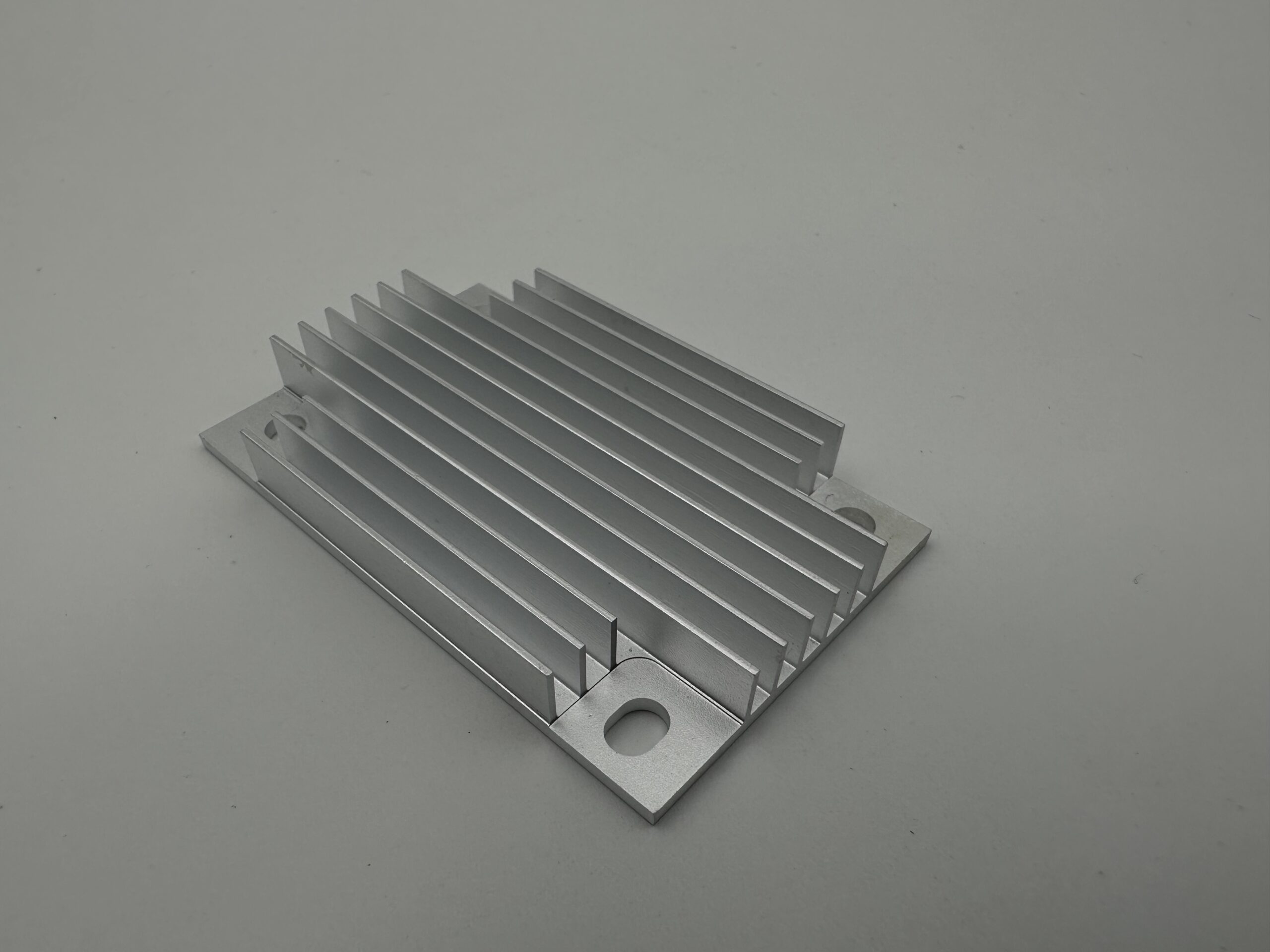

Extruded heat sinks can be tailored into a wide range of shapes, sizes, and fin structures by simply changing the extrusion die. Thanks to their flexibility, they are ideal for various thermal management needs across different industries.

Supports Secondary Machining

After extrusion, the profiles can undergo further processing such as CNC machining, drilling, or cutting. These secondary operations enable precise customization, allowing the heat sink to be adapted for specific mounting or integration requirements in complex assemblies.

Why Choose Dingmetal

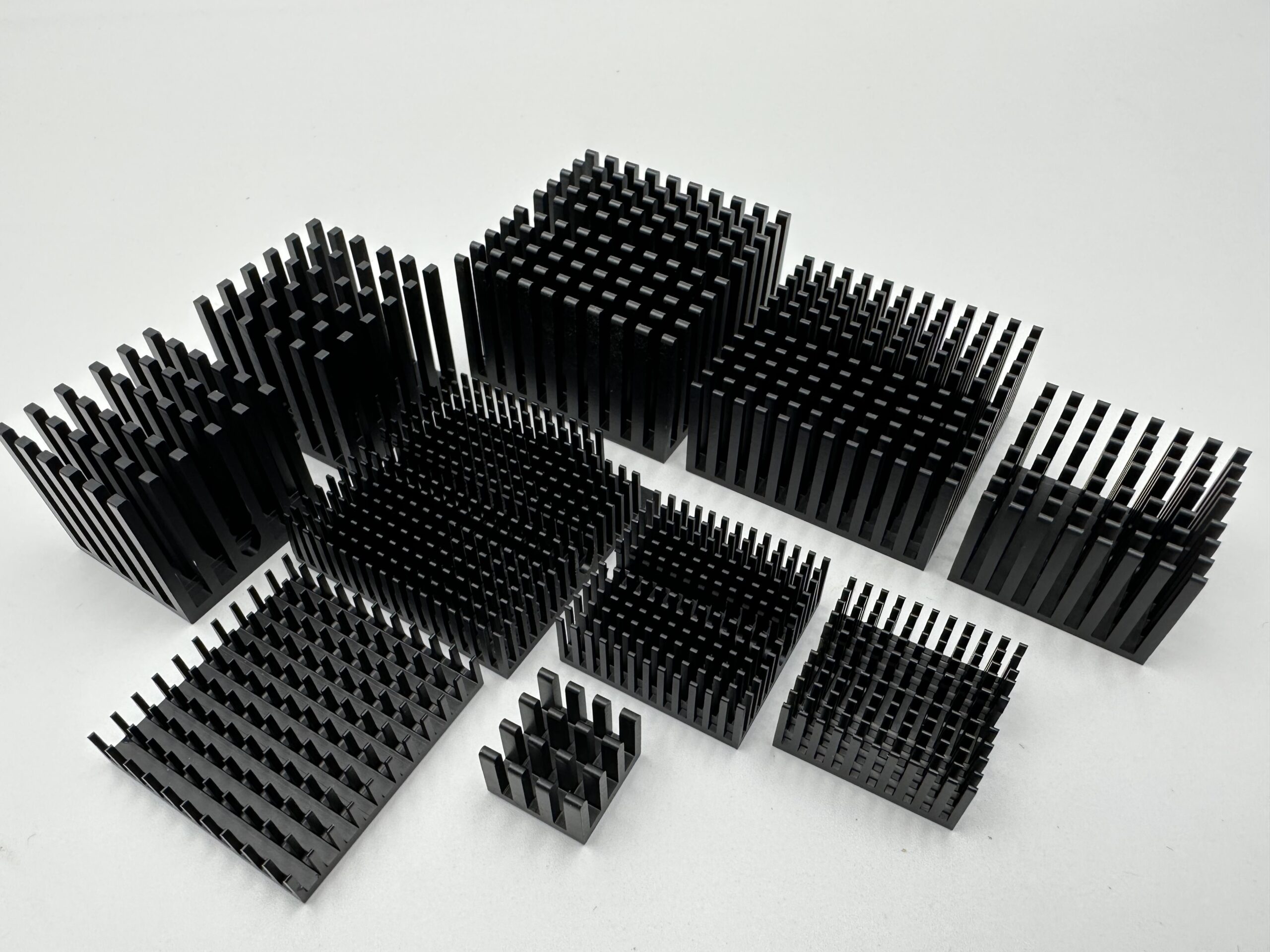

- Wide Selection

Dingmetal has specialized in heat sink manufacturing for over 10 years, offering an extensive range of options to meet the diverse needs of various industries. Our selection includes BGA heat sinks, cold-forged heat sinks, die-casting heat sinks, extrusion heat sinks, heat pipe heat sinks, machined heat sinks, and skived heat sinks. No matter the application, we have the right solution to ensure optimal thermal performance for your devices.

- Highly Customizable Options

With over 90% of our products being custom-made, we take pride in our ability to provide tailored solutions for specific requirements. Thanks to our superior manufacturing capabilities, we can produce highly customized heat sinks that match your exact needs, Whether adjusting the design, material, or size.

- Low MOQ for Flexible Ordering

At Dingmetal, we cater to a wide range of order sizes with a low minimum order quantity. For standard heat sinks, the MOQ starts at just 10 pieces, while for custom heat sinks, the MOQ begins at 50 pieces. With enhanced flexibility, we can accommodate businesses of all sizes, allowing you to order precisely what you need, whether for small-scale prototypes or large production runs.

Applications of Extruded Heat Sinks

Our extruded heat sinks have broad applications in electronics, the automotive industry, and industrial machinery. In electronics, they help dissipate heat from components like power transistors, voltage regulators, and ICs. In industrial equipment, they are commonly used for cooling motor drives, inverters, and control systems. In the automotive sector, extruded heat sinks support the thermal regulation of onboard electronics, including power control units and battery management systems, ensuring stable operation in demanding environments.

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap