- Sorry, this product cannot be purchased.

Products

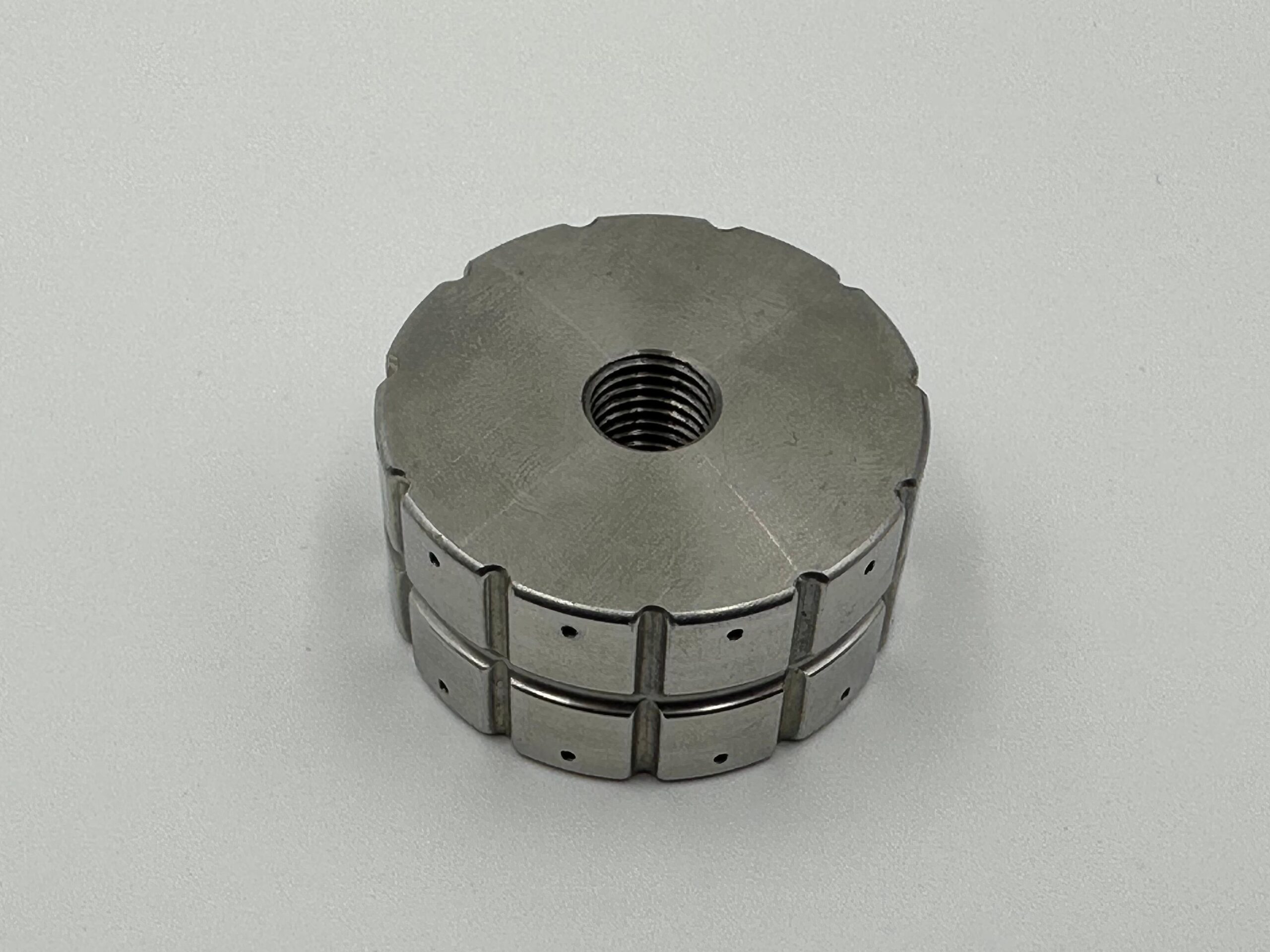

Precision Turning

What is Precision Turning?

Precision turning is used to produce cylindrical components with tight tolerances and superior surface finishes. As a specialized form of CNC turning, it involves rotating a metal or plastic workpiece at high speed. Meanwhile, a cutting tool precisely removes material to achieve the desired shape, dimension, and finish.

At Dingmetal, we specialize in manufacturing precision turned parts by combining skilled craftsmanship with advanced, fully automated CNC-turning equipment. Our cutting-edge technology ensures exceptional consistency, accuracy, and efficiency, even for complex geometries or high-volume runs.

Material Options for Precision Turning Parts

Dingmetal offers various material options to suit application needs. Selecting the appropriate material is crucial to ensure performance, durability, and cost-effectiveness in precision turning parts.

Excellent electrical and thermal conductivity. Ideal for electrical components, connectors, and heat dissipation applications.

Lightweight yet strong, with good corrosion resistance. Commonly used in aerospace, automotive, and electronics industries.

High strength and durability. Suitable for mechanical parts and structural components that require toughness.

Tailored properties such as wear resistance, hardness, and corrosion resistance. Alloys are chosen based on specific performance demands.

Key Features of Precision Turned Parts

High Precision

Precision turned parts are recognized for their tight dimensional tolerances, ensuring consistent quality and reliable fit across production runs. The process offers excellent repeatability, making it ideal for high-accuracy applications.

Complex Geometry Capability

Precision turning accommodates intricate designs through multi-axis machining. It allows for features such as threading, drilling, and chamfering to be integrated into a single setup, enabling efficient production of complex parts.

Quick Turnaround

Precision turning parts rely on CNC automation and efficient workflows, which reduce lead times for faster prototyping, flexible order handling, and reliable on-time delivery. Ideal for small customized batches and large-scale production.

Why Choose Precision Turned Components

from Dingmetal

- Reliable Production Capacity

With extensive CNC machining centers and automated production lines, Dingmetal handles high-volume orders with consistent quality. We have developed an efficient workflow system to ensure stable output, making us a dependable supplier of standard and custom precision-turned parts.

- Wide Product Selection

We offer a broad range of turned components made from materials such as aluminum, brass, and stainless steel. Whether you require standard sizes or complex custom parts, we deliver professional, cost-effective solutions with guaranteed supply consistency.

- Proven Technical Expertise

Backed by over 20 years of experience in precision machining, our engineering team understands the technical challenges behind every detail. From prototyping to full-scale production, we apply industry knowledge to deliver components with excellent accuracy and performance.

Applications of Our Precision Turned Parts

Our custom precision-turned components are widely used in aerospace, AI liquid cooling systems, medical equipment, and electronics. Built for high performance and reliability, our parts support complex assemblies and critical applications. Explore our cases and request your custom quote today!

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap