- Sorry, this product cannot be purchased.

Products

Thermoelectric Cooler Assemblies

What are Thermoelectric Cooler Assemblies

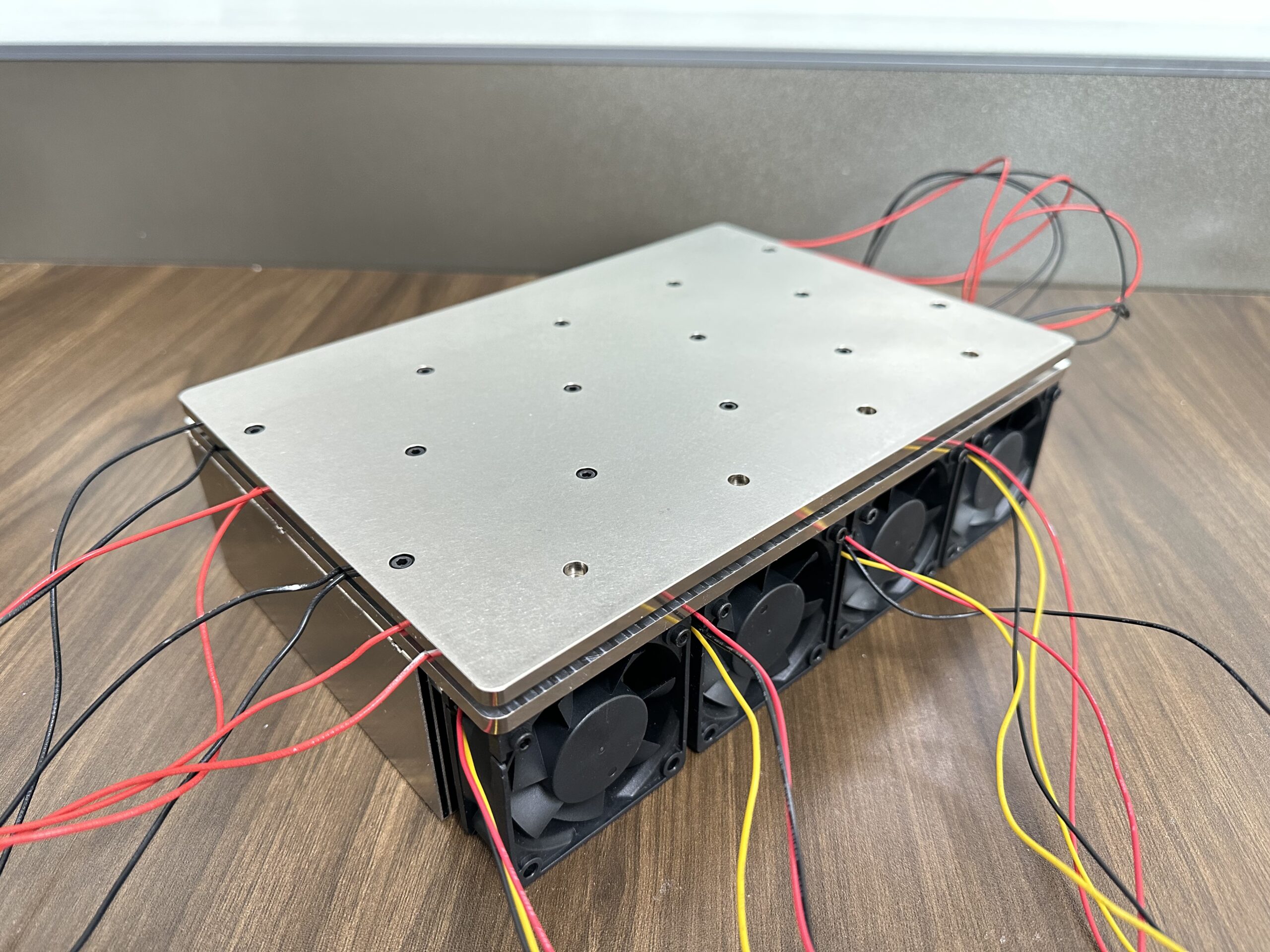

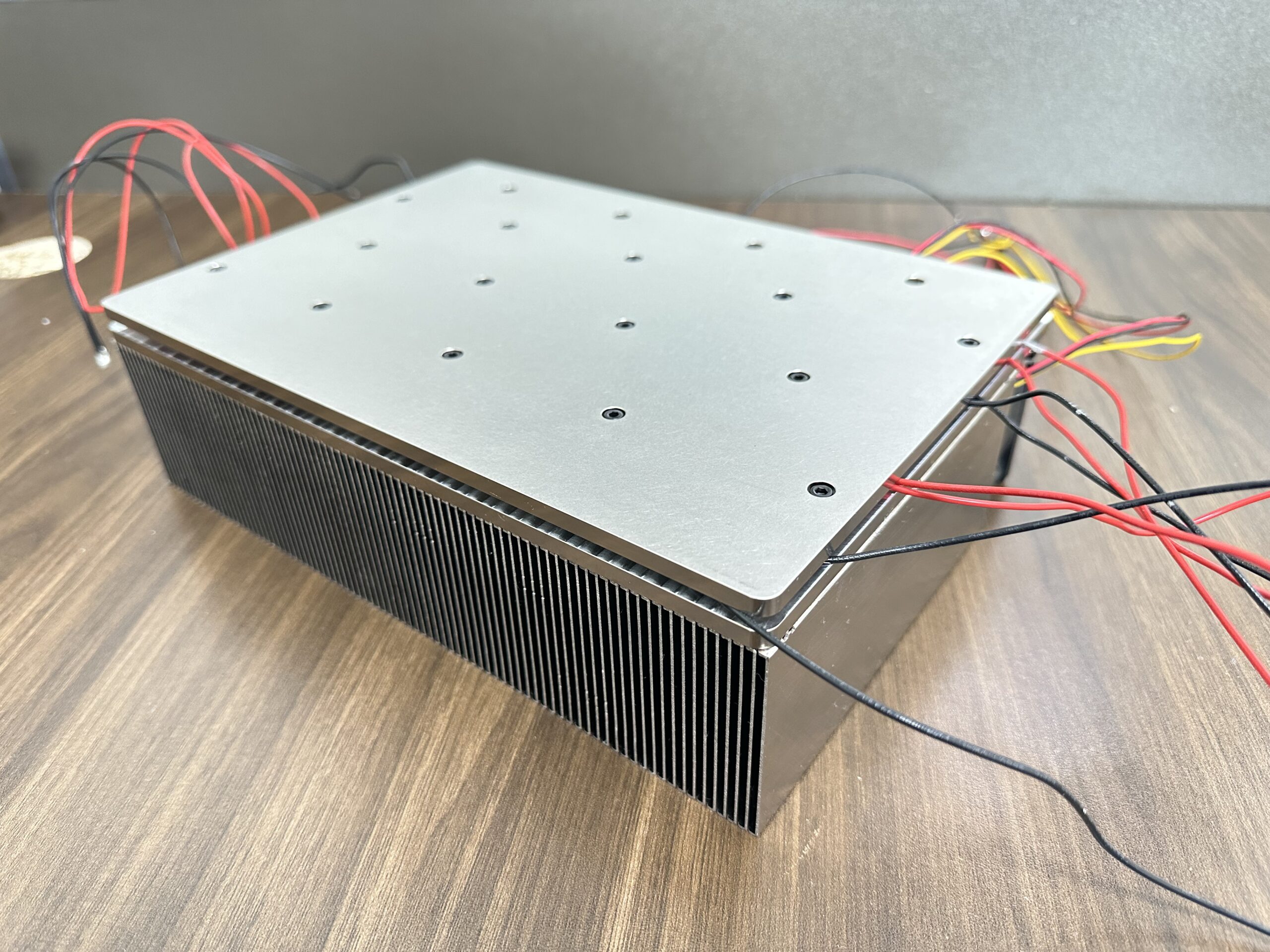

Thermoelectric Cooler Assemblies (TECA) – Reliable Solid-State Temperature Control

Thermoelectric Cooler Assemblies, powered by advanced Peltier technology, are compact, solid-state thermal management systems that provide precise heating and cooling. By integrating thermoelectric modules with heat sinks, fans, or liquid cold plates, these assemblies efficiently regulate temperatures without the need for refrigerants or compressors. With no moving parts in the core cooling mechanism, they offer reliable, low-maintenance performance.

Core Structure of TECA

A TECA (Thermoelectric Cooling Assembly) is built on a precise structure that integrates core thermoelectric modules with carefully engineered hot and cold side assemblies. This design enables effective heat transfer and ensures reliable cooling performance across diverse applications.

At the heart of every TECA is a thermoelectric module composed of P-type and N-type semiconductor elements. The thermoelectric module utilizes the Peltier effect to create a temperature differential when voltage is applied, absorbing heat on one side and releasing it on the other.

The heat generated by the TEC chip is removed through the hot side structure, which typically includes heat sinks, fans, or liquid cold plates. These components ensure efficient heat dissipation and maintain stable performance.

The cold side is in direct contact with the target object or surface requiring cooling. It may include mounting plates or interface materials to enhance thermal conductivity and ensure effective heat absorption from the application area.

Advantages of Thermoelectric Cooling Assemblies

Precise Temperature Control

Thermoelectric cooling assembly systems provide exceptional thermal accuracy, often maintaining temperature stability within ±1°C. With precise control, it is essential for applications involving sensitive components, such as laser diodes, medical diagnostic instruments, and high-precision sensors, where even slight temperature fluctuations can affect performance.

Dual-Mode Operation

Thermoelectric cooler assemblies support cooling and heating by simply reversing the input voltage polarity. Featuring this dual-mode capability, the TECA system eliminates the need for separate heating elements, reducing complexity and saving valuable space in compact device designs.

High Reliability

With no moving parts in the thermoelectric module and no reliance on refrigerants or compressors, TECA units deliver quiet, maintenance-free operation and extended service life. These assemblies can provide stable performance in harsh or vibration-sensitive environments due to their solid-state design.

Why Choose Dingmetal

- Experienced Management

Our leadership team brings over 15 years of experience managing large-scale operations in multinational companies, ensuring that industry best practices are always implemented.

- Controlled Processes

We utilize EMS program controls and adhere to PPAP and APQP methodologies to ensure process consistency, reliability, and quality.

- Fully Integrated Manufacturing Process

From design to production, we operate a fully self-sustained factory that allows us to control every step of the process.

Common Applications of

Thermoelectric Cooler Assemblies

Thermoelectric cooler assemblies are widely adopted across industries where precise, reliable, and compact thermal management is essential.

Maintain precise temperature control in blood analyzers, PCR equipment, and reagent storage (typically 4–8°C).

Efficient thermal management for laser diodes, CPUs, image sensors, and other heat-sensitive components.

Ideal for HPLC systems, aerospace instrumentation, and industrial automation where thermal stability is crucial.

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap