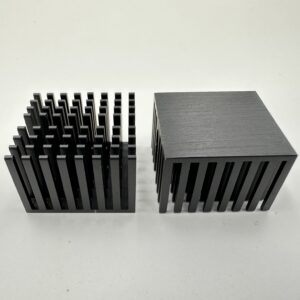

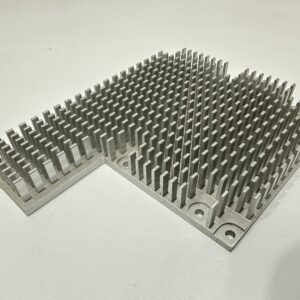

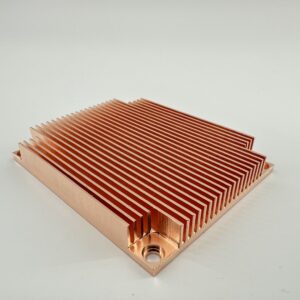

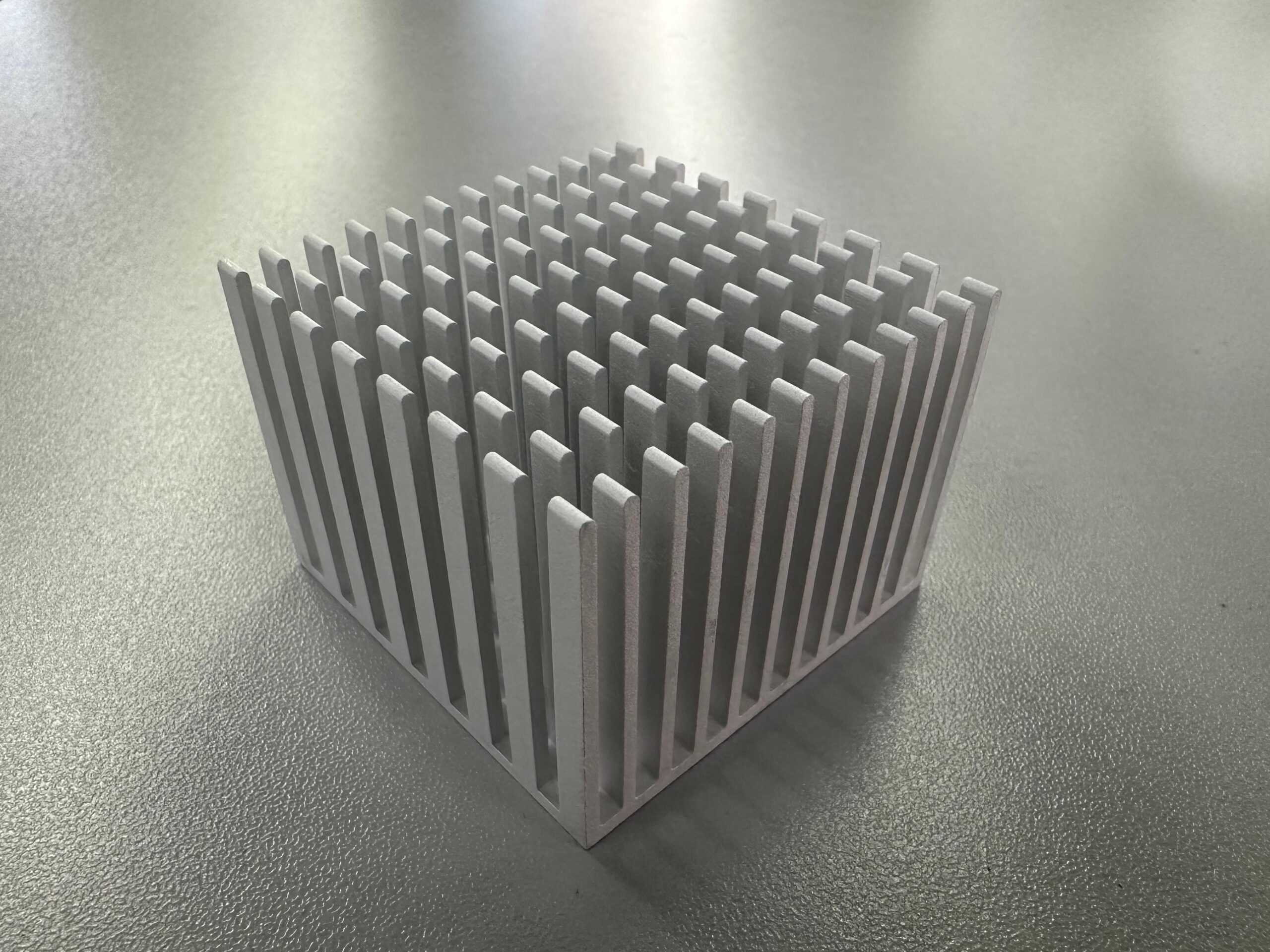

Professional Heat Sink Solutions: Customization & Manufacturing

Dingmetal is a China-based custom heatsink manufacturer, specializing in tailor-made thermal solutions built to your layout or design. Our products are widely used in electronics, telecom, EVs, LED lighting, and industrial equipment—anywhere efficient heat dissipation is required.

- 10+ years of manufacturing experience

- The delivery time is as short as 7 days

- The tolerance is as low as 0.02mm

- Engineers help your design to final manufacturing

Our Heatsink Machining Capabilities

We use advanced multi-axis CNC technology and tooling to address the challengesassociated with machinina heatsink fins

Processing Technology

Advanced 3-axis, 4-axis, and 5-axis CNC machining (FANUC, Mazak) for precision turning, milling, and contouring of complex heatsink designs.

Precision & Equipment

Over 50 CNC machining centers deliver ±0.02 mm accuracy and stable repeatability — ideal for prototypes and mass production.

Materials

Aluminum and copper as standard; stainless steel, brass, titanium, and engineering plastics available on request.

Surface Finishing

Anodizing, sandblasting, powder coating, electroplating, polishing, and laser engraving — customized finishes supported.

Production Speed

Rapid prototyping and flexible mass production. Typical lead times: 3 weeks for samples, 4–6 weeks for bulk orders.

Customization Options

Dingmetal provide high precision mass-produced heat sinks with complex features, cut-outs, through-holes, and so on.

Geometry Adjustments: Change height, base size, or overall dimensions.

Surface Finish Options: Choose from various surface treatments for performance or appearance.

Structural Modifications: Add through holes, tapped holes, or pedestals as needed.

Assembly Features: Integrate push-pins, shoulder screws, or thermal interface materials (TIM).

Why Choose Dingmetal as Your

Heat Sink Supplier

- Wide Selection

Dingmetal has over 10 years of experience in heat sink manufacturing, offering a wide range of heat sinks solutions — trusted across telecom, data centers, EVs, LED lighting, industrial systems, and medical devices. Backed by a 20,000 m² advanced facility with CNC machining, extrusion, forging, and die-casting lines, we deliver reliable thermal performance, consistent quality, and scalable production to meet your demanding applications.

- Highly Customizable Options

We handle parts from drawings or complex 3D designs, offering rapid prototyping and small-batch production within 7 days for urgent projects. With materials including aluminum, copper, stainless steel, iron, and engineering plastics, and surface treatments such as anodizing, nickel plating, passivation, and powder coating, Dingmetal ensures precise, durable, and high-quality heat sinks that help you accelerate time-to-market.

- Low MOQ for Flexible Ordering

Whether you need small-batch samples or full-scale production, Dingmetal adapts to your purchasing plan. MOQ starts from 10 pcs for standard models and 50 pcs for custom units, ensuring smooth transition from R&D to mass production.

How to Work with Us for

Custom Heat Sinks

Step 1: Design and Discussion

We start by discussing your specific requirements and exploring design options for your custom heat sinks to meet your thermal and mechanical needs.

Step 2: Quotation

After finalizing the design, we provide a detailed quotation that includes pricing and lead times, ensuring complete transparency to help you make informed decisions.

Step 3: Sample Production

Upon confirming the quotation, we will send a sample for your approval, allowing you to assess the performance and quality.

Step 4: Customer Approval

Once you approve the sample, we will make any final adjustments if needed and then prepare for mass manufacturing of the heat sinks.

Step 5: Official Molding

Upon sample approval, we enter the official molding process to create the custom heat sinks for large-scale production, ensuring consistency and precision in every unit produced.

Step 6: Mass Production

Once the molds are finalized, we move to mass production. Our team maintains high standards and ensures on-time delivery for your order.

FAQs on Heat Sink Manufacturing

Find answers to the common questions about our custom heatsinks!

For standard heat sinks in stock, we offer a minimum order quantity of 10 pieces. For custom heat sinks, the MOQ typically starts at 50 pieces, depending on the complexity and specifications.

For the initial order, we require 100% payment via T/T before shipment. For subsequent orders, we can accommodate payment terms based on an agreed-upon credit period, offering flexibility to meet your business needs.

Yes. As a heat sink supplier with years of experience, we provide assembly services tailored to your requirements. We work closely with clients to ensure that the assembly process aligns with specific needs, delivering a fully integrated solution.

Parameter | Custom Heat Sink |

Process | Raw Material → Rough Machining → Precision Machining → Surface Treatment → Welding or Assembly → Testing → Packaging |

Materials | Various Grades of Copper, Aluminum, Stainless Steel, Iron, and Engineering Plastics |

Shapes | Based on your requirements. |

Color | Based on your requirements. |

Technical | extrusion, skived fin, stamping, cold forging, bonded fin, die cast, liquid cold plates, folded fin, etc |

Finish | Anodizing, Nickel Plating, Passivation, Powder Coating |

Deep process | Secondary Milling, Reshaping |

MOQ | Supports orders of any quantity — from prototypes to mass production |

Certificate | IATF16949,ISO14001,IATF16949 and so on |

Service | 1.Free design; 2. OEM/ODM available; 3. Custom-made request; 4. New design solution suggestion |

Delivery time | 7–35 days, depending on product type and complexity |

Application | Widely used in telecommunication, communication equipment, data centers, automotive, and other industries |

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap