Efficient thermal management is critical for modern electronic devices, especially as power density continues to increase. Among the most common air-cooling solutions, skived and extruded heat sinks are widely used across industrial, automotive, telecom, and power-electronics applications. While both serve the same fundamental purpose, their manufacturing processes, performance characteristics, and ideal use cases differ significantly. This article explains the key differences to help you choose the right type for your application.

What is a Skived Heat Sink

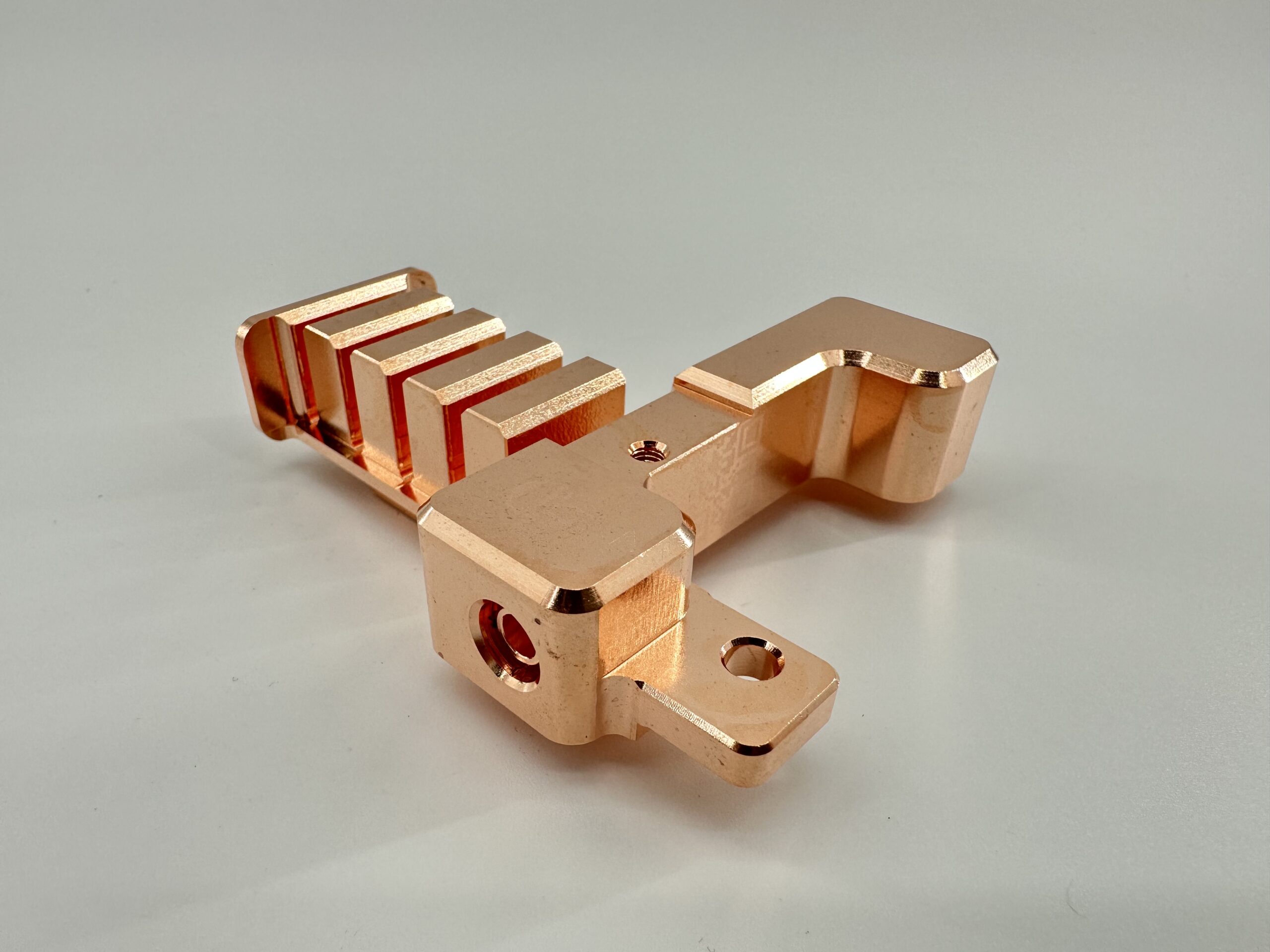

A skived heat sink is manufactured using a skiving process, where thin fins are precisely cut and lifted from a solid block of metal, typically aluminum or copper, without separating them from the base material. Because the fins are formed from the same piece of metal, there is no thermal interface between the base and the fins.

This process allows skived heat sinks to achieve extremely high fin density and thin fin profiles that are difficult or impossible to produce using extrusion. Copper-skived heat sinks are particularly popular in high-power applications due to copper’s superior thermal conductivity.

Benefits of Skived Heat Sinks

Skived heat sinks offer several performance-driven advantages:

High thermal performance

The continuous metal structure between the base and fins minimizes thermal resistance, enabling efficient heat transfer.

High fin density in compact spaces

Skiving enables very thin fins with tight spacing, maximizing surface area within limited footprints.

Material flexibility

Both aluminum and copper can be used, making skived heat sinks suitable for high-power and high-heat-flux applications.

Low tooling cost for custom designs

Compared to extrusion dies, skiving tools are relatively simple, making custom or low- to medium-volume production more economical.

Due to these advantages, skived heat sinks are commonly used in power electronics, inverters, EV charging systems, IGBT modules, and high-performance industrial equipment.

What is an Extruded Heat Sink

An extruded heat sink is produced through the aluminum extrusion process. Heated aluminum billets are forced through a shaped die to create a continuous profile, which is then cut to length. Extrusion is one of the most widely used and cost-effective manufacturing methods for heat sinks.

Extruded heat sinks are typically made from aluminum alloys and are available in a wide range of standard profiles, making them easy to source and suitable for mass production.

Benefits of Extruded Heat Sinks

Extruded heat sinks are valued for their practicality and cost efficiency:

Cost-effective for high-volume production

Once the extrusion die is made, large quantities can be produced at a low unit cost.

Consistent quality and dimensional stability

The extrusion process ensures uniform cross-sections and reliable repeatability.

Wide availability of standard profiles

Many off-the-shelf designs are readily available, reducing lead times.

Good performance for moderate power levels

Extruded heat sinks provide sufficient cooling for many standard electronic applications.

Because of these characteristics, extruded heat sinks are commonly used in consumer electronics, LED lighting, power supplies, communication devices, and general industrial electronics.

Skived vs Extruded Heat Sinks Comparison

| Feature | Skived Heat Sink | Extruded Heat Sink |

| Manufacturing process | Skiving from solid block | Aluminum extrusion |

| Fin density | Very high | Limited by extrusion |

| Fin thickness | Very thin | Thicker |

| Thermal performance | High to very high | Moderate |

| Materials | Aluminum, copper | Aluminum only |

| Tooling cost | Low | Moderate |

| Unit cost | Higher | Lower |

| Best use cases | High power, compact designs | Standard power, mass production |

How to Choose the Right Type

Choosing between skived and extruded heat sinks depends on your thermal requirements, space constraints, and budget.

Select a skived heat sink if your application involves high power density, limited installation space, or requires superior thermal performance. Skived designs are especially suitable when traditional extruded heat sinks cannot dissipate heat effectively enough.

On the other hand, choose an extruded heat sink if your application has moderate thermal demands, sufficient space, and a strong focus on cost control and scalability. Extruded heat sinks remain an excellent solution for high-volume production and standardized designs.

In many thermal management projects, the optimal solution balances performance, manufacturability, and cost. Understanding the strengths and limitations of skived and extruded heat sinks is the first step toward designing an efficient and reliable cooling system.

As a professional heat sink manufacturer, Dingmetal brings over 10 years of hands-on experience in the design and manufacturing of skived and extruded heat sinks. With in-house production capabilities and a deep understanding of application-specific thermal requirements, we support customers across industrial electronics, power systems, and high-performance applications by delivering reliable, high-quality thermal solutions tailored to their needs.