As devices become increasingly compact and powerful, choosing the right heat sink material becomes just as important as selecting the right heat sink design. Each material influences thermal conductivity, weight, cost, manufacturing feasibility, and long-term durability. This article guides you through common heat sink materials, key factors to consider, and how to choose the right one for your specific application.

Common Materials for Heat Sinks

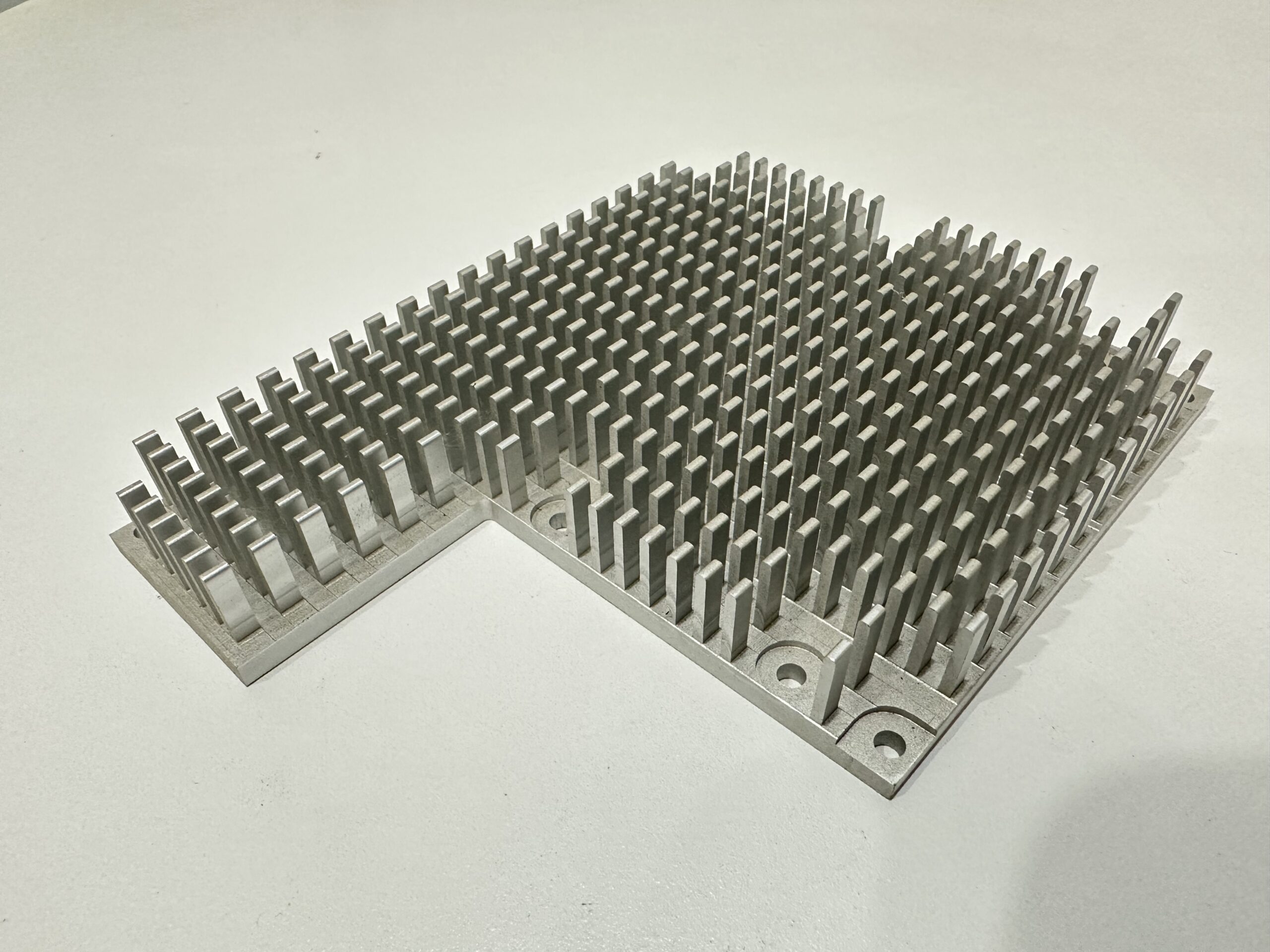

Aluminum

As one of the most widely used heatsink materials, aluminum strikes an excellent balance between performance and manufacturability. With a thermal conductivity of about 205 W/m·K, it offers sufficient heat dissipation for most consumer electronics, LED lighting, and industrial devices. Its low density allows for lightweight designs, and processes such as extrusion, die casting, and machining can create complex fin shapes at competitive costs. Additionally, aluminum naturally forms an oxide layer that provides corrosion protection and supports anodized finishes.

Copper

Copper features an outstanding thermal conductivity of approximately 385 W/m·K, nearly double that of aluminum. This makes it the preferred choice for high-heat-flux environments such as CPUs, GPUs, power modules, and high-performance telecom or industrial equipment. Its higher density and cost make it less suitable for large-volume or weight-sensitive designs. Copper is more challenging to form in extrusion or die casting. But it excels in machined bases, heat pipes, vapor chambers, and hybrid copper-aluminum structures.

Brass

Brass offers higher strength and better machining characteristics compared to pure copper, while providing moderate thermal conductivity (≈110 W/m·K). It is often used for connector housings, threaded heat sink components, or decorative thermal parts where aesthetics, mechanical precision, or corrosion resistance matter. Brass is not typically used for primary heat dissipation in modern electronics, but can serve as a supporting structure in thermal assemblies.

What to Consider When Choosing Heat Sink Materials

- Thermal Conductivity Requirements

Prioritize materials with high conductivity if your device generates high heat in a compact area or requires rapid heat spreading, typically copper or copper hybrids.

- Weight Constraints

For portable electronics, LED fixtures, drones, and aerospace-related systems, minimizing weight is essential. Aluminum is generally the best solution in these cases.

- Cost and Production Volume

Material cost, machining difficulty, and tooling requirements all influence total manufacturing cost.

Aluminum is ideal for mass production. Copper is suitable for low-volume or high-performance systems. Brass is used for mechanical or aesthetic functions, not for thermal optimization.

- Manufacturability

Some manufacturing methods, such as extrusion, die casting, skiving, or bonded-fin assembly, work significantly better with aluminum. Copper may require machining or brazing, which increases cost and complexity.

- Environmental and Corrosion Conditions

Aluminum is naturally corrosion-resistant. Copper may require surface treatment depending on humidity or chemical exposure.

- Integration with Heat Pipes or Vapor Chambers

Copper is typically preferred for vapor chambers and heat pipes due to compatibility with working fluids and strong brazing performance.

Choosing the Right Material for Your Heat Sink

To determine the best material for heat sinks, start by evaluating:

- Heat load and temperature limits

High heat → Copper or Cu-Al hybrid

Medium to low heat → Aluminum is often sufficient.

- Dimensional and weight restrictions

Tight weight limits → Aluminum

High mass acceptable → Copper

- Product cost targets

Tight budget / large volume → Extruded or die-cast aluminum

High-performance specialty product → Copper or hybrid solutions

- Manufacturing processes needed

Complex fins, thin walls → Aluminum

Heat pipes, vapor chambers → Copper

- Environmental conditions

Corrosive or outdoor use → Stainless steel or coated aluminum

Precision mechanical parts → Brass

Ultimately, no single material is universally BEST. The ideal choice depends on achieving the right balance between thermal performance, mechanical properties, cost, and application constraints.

Reliable Solutions from Dingmetal

Selecting the appropriate heat sink material is crucial for achieving stable performance and long-term reliability in modern electronic designs. With over a decade of experience in heat sinks manufacturing, thermal assemblies, and precision metal fabrication, Dingmetal provides tailored solutions across aluminum, copper, hybrid structures, and advanced manufacturing processes. Whether you need mass-production extrusions or high-performance copper modules, our engineers can help you determine the optimal material and design for your application.