There are many ways to categorize heat sinks, such as by cooling method, the devices they support, material, or manufacturing process. Among these, the manufacturing process affects thermal performance, cost, and design flexibility in a heat sink. In this article, we will explore the most common types of heat sinks classified by this aspect and compare their characteristics and typical applications.

What Is a Heat Sink?

Known for thermal components, heat sinks dissipate heat from electronic devices into the surrounding air. They can help maintain optimal operating temperatures for CPUs, power transistors, LEDs, and EV chargers by increasing their surface area in contact with the air. Though they serve the same purpose, their performance can vary significantly based on their manufacturing process.

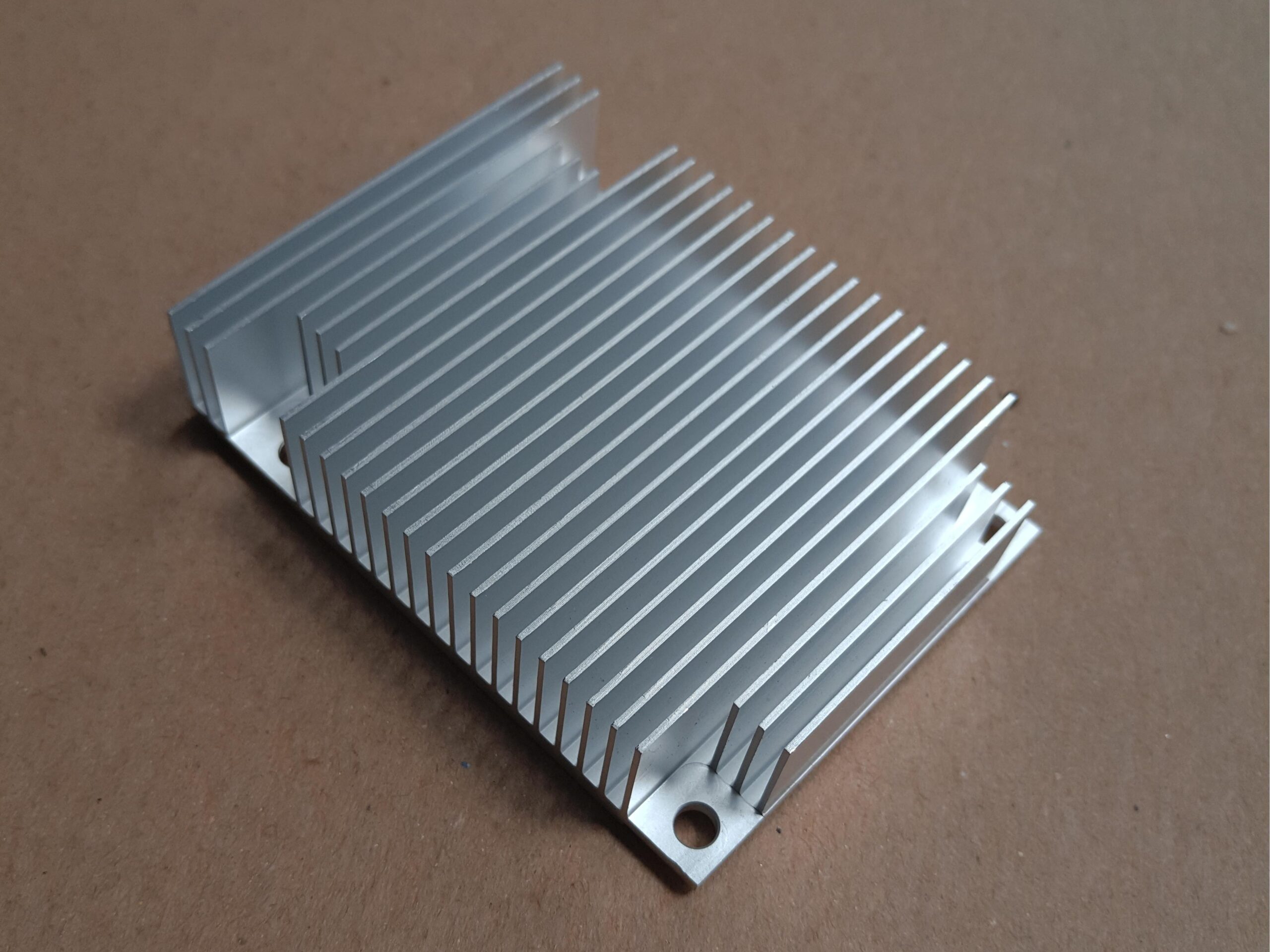

1. Extruded Heat Sinks

Aluminum billets are initially heated to temperatures suitable for extrusion(around 350-500℃). They are then forced through a die to produce continuous profiles with intricate fin structures.

Advantages: Cost-effective, good thermal conductivity, and easy to customize for various lengths and shapes.

Applications: consumer electronics, power modules, LED lighting.

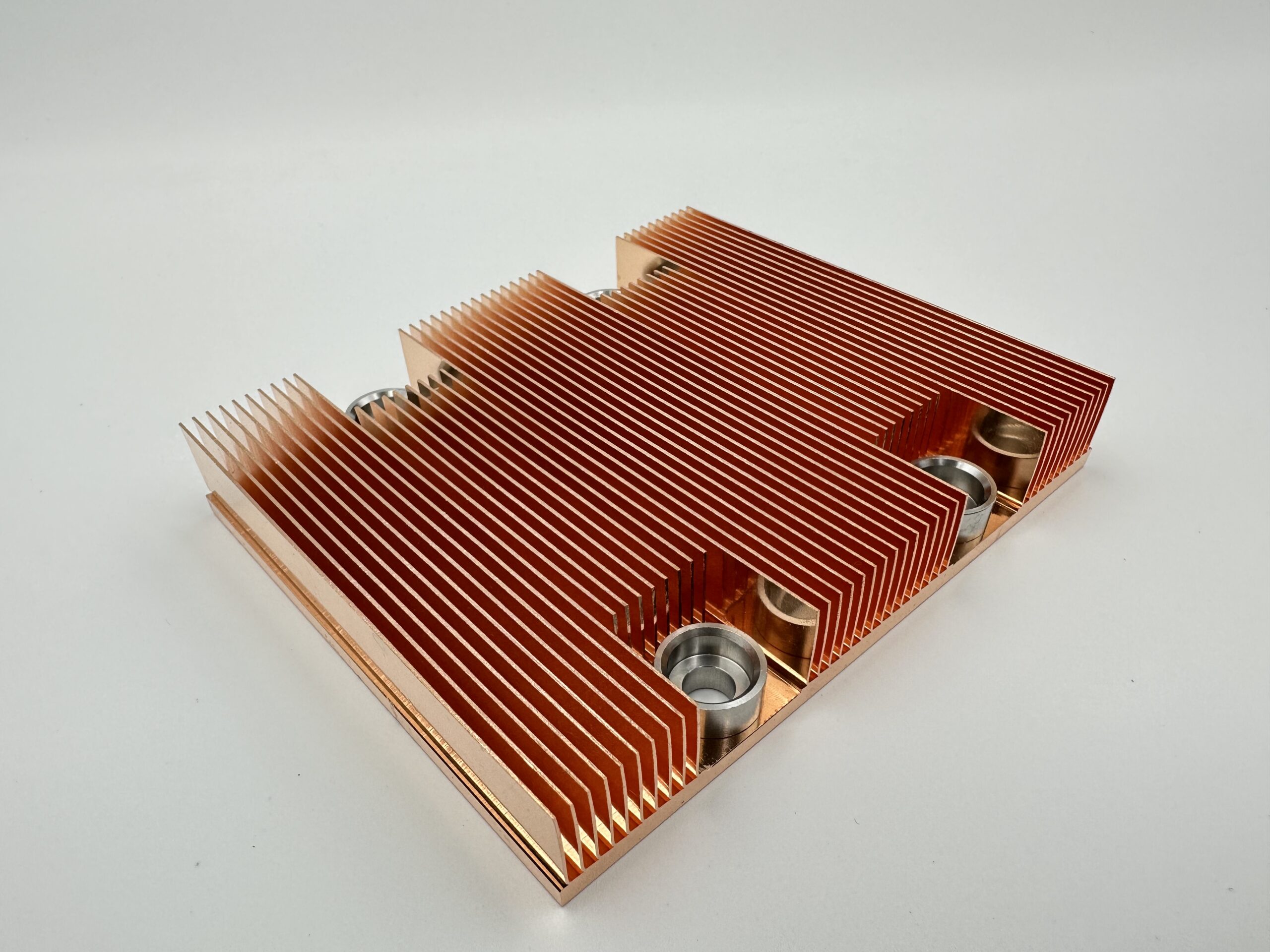

2. Skived Heat Sinks

Skived fins are created by cutting thin layers from a solid metal block and bending them upward to form high-density fins. The skiving process can be more expensive, but it provides superior heat dissipation efficiency.

Advantages: Excellent thermal performance due to continuous grain structure between fins and base; suitable for high heat flux applications.

Applications: Server systems, high-performance computing, and automotive electronics.

3. Forged Heat Sinks

Cold forging or hot forging compresses aluminum or copper under high pressure into a desired shape using a die, enabling exceptional durability in harsh operating conditions.

Advantages: High strength, excellent thermal conductivity, and the ability to create dense pin-fin structures.

Applications: Compact devices and environments with limited airflow, such as telecom equipment and automotive control units.

4. CNC-Machined Heat Sinks

CNC machining involves the precise cutting of heat sink geometry from a solid block of metal. Therefore, it requires higher production costs.

Advantages: Extremely high precision and design flexibility; suitable for prototypes or complex custom shapes.

Applications: Aerospace, laboratory equipment, and performance testing systems.

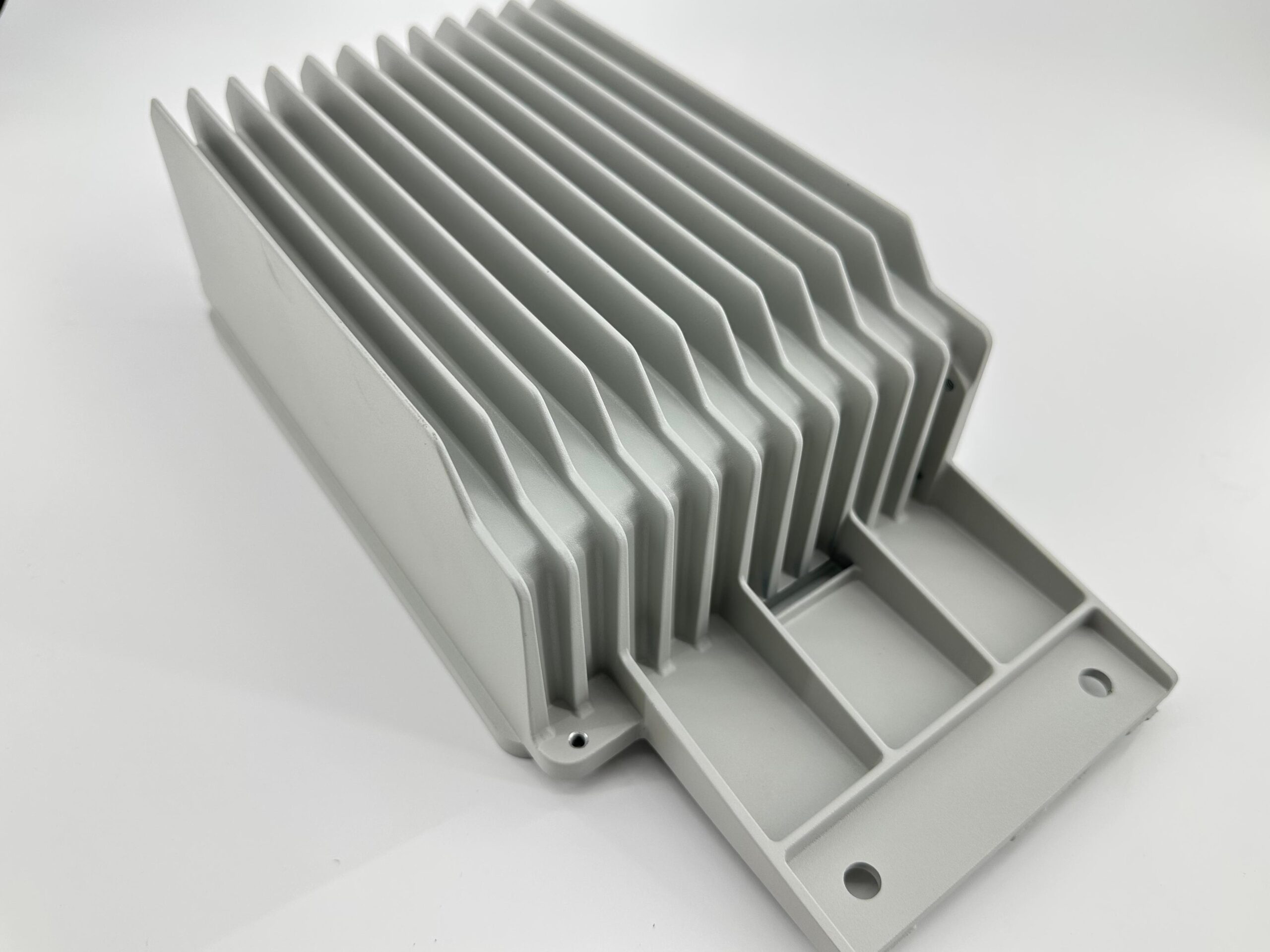

5. Die-Cast Heat Sinks

Die casting uses molten aluminum or zinc alloy injected into a steel mold under high pressure.

Advantages: High production efficiency, good surface finish, and support for integrated complex structures.

Applications: Consumer electronics, LED housings, and industrial power supplies.

6. Bonded Fin Heat Sinks

A bonded-fin heat sink consists of fins individually attached to the base plate using thermal epoxy, brazing, or soldering.

Advantages: Flexible in design, supports different materials (like copper fins on an aluminum base), and allows very high aspect ratios.

Applications: High-power converters, industrial drives, and EV chargers.

Choosing the Right Type of Heat Sink

Different Types of Heat Sink Comparison (By Manufacturing Process)

| Types of Heatsinks | Thermal Performance | Cost | Lead Time | Design Flexibility |

| Extruded | ★★☆ | ★★☆ | ★★☆ | ★★☆ |

| Skived | ★★★ | ★☆☆ | ★☆☆ | ★★☆ |

| Forged | ★★★ | ★★☆ | ★★☆ | ★★☆ |

| CNC Machined | ★★★ | ★☆☆ | ★☆☆ | ★★★ |

| Die-Cast | ★★☆ | ★★★ | ★★★ | ★☆☆ |

| Bonded Fin | ★★★ | ★★☆ | ★★☆ | ★★★ |

The above compares different types of heat sinks. Typically, factors to consider include heat load, airflow conditions, available space, weight limits, and cost. Understanding the differences between manufacturing methods helps you achieve an optimal balance between performance and practicality.

Choosing the Right Heatsink Manufacturer

As an experienced heatsink manufacturer, Dingmetal has accumulated over 10 years of expertise in design and production. From extrusion and forging to precision CNC machining, our team helps develop tailored solutions to meet the unique requirements of your applications.