In the technology-driven world, electronic devices such as laptops, smartphones, and power modules have become indispensable in work and everyday life. However, as these devices become more powerful and compact, they generate significant heat, which, if not properly managed, can lead to performance degradation or even failure.

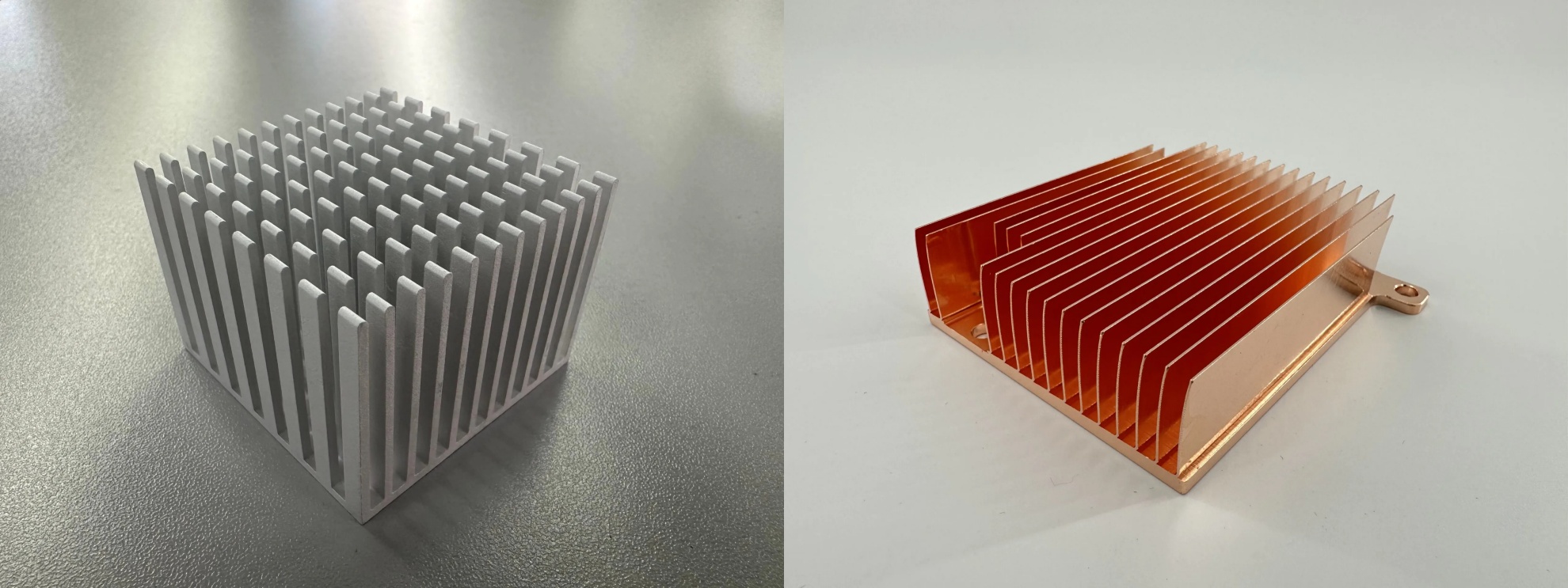

Heat sinks solve this challenge by providing efficient thermal dissipation. Among various materials used, aluminum and copper are the two most common choices. In this article, we will take a closer look at copper vs. aluminum heat sinks, comparing their thermal properties, cost, weight, and suitability for different applications to help you make an informed decision.

Key Properties

| Thermal conductivity ( W/m·K) | Copper (~385) > Aluminum(~205) |

| Density (g/cm³) | Copper(8.96 ) > Aluminum (2.70) |

| Cost (Raw material & processing) | Copper > Aluminum |

The chart lists some key properties of copper vs aluminum heatsinks. But what on earth does it mean? Let us break it down one by one.

Copper’s higher thermal conductivity means that for the same geometry and volume, it conducts heat away from a hot spot faster and spreads heat more evenly across the base and fins.

Copper’s higher density means it absorbs and buffers transient heat pulses better because its higher mass and heat capacity allow it to store more thermal energy before temperature rises significantly. This is particularly useful in pulsed-load applications.

The cost for raw materials and processing is understandable. Aluminum is easier and cheaper to extrude, die-cast, or skive at scale. Therefore, it is a preferred material option for cost-sensitive, high-volume products.

| Thermal conductivity ( W/m·K) | Copper (~385) > Aluminum(~205) |

| Density (g/cm³) | Copper(8.96 ) > Aluminum (2.70) |

| Cost (Raw material & processing) | Copper > Aluminum |

The chart lists some key properties of copper vs aluminum heatsinks. But what on earth does it mean? Let us break it down one by one.

Copper’s higher thermal conductivity means that for the same geometry and volume, it conducts heat away from a hot spot faster and spreads heat more evenly across the base and fins.

Copper’s higher density means it absorbs and buffers transient heat pulses better because its higher mass and heat capacity allow it to store more thermal energy before temperature rises significantly. This is particularly useful in pulsed-load applications.

The cost for raw materials and processing is understandable. Aluminum is easier and cheaper to extrude, die-cast, or skive at scale. Therefore, it is a preferred material option for cost-sensitive, high-volume products.

Pros & Cons Analysis

Based on the key properties, the pros and cons of copper and aluminium heat sinks are obvious.

| Materials | Pros | Cons |

| Copper |

|

|

| Aluminum |

|

|

Common Application & Selecting Guidelines

Copper heat sinks are widely applied in high-power electronics, compact high-density systems, and pulsed & transient load applications. Aluminium heat sinks are ideal for consumer electronics, LED lighting, power supplies, and industrial & automotive applications. Additionally, hybrid solutions, such as a copper base and aluminum fins, have been used for balancing heat spreading and weight in high-performance laptop cooling, graphics card coolers, and more.

Dingmetal, as an experienced heatsink supplier, summarizes the general selection guidelines for copper and aluminum materials based on years of thermal design and manufacturing experience. By understanding the characteristics of each metal, engineers and product designers can select the most suitable material that meets both performance and cost requirements in their specific applications.

Choose Copper when:

Maximum thermal performance is critical.

Weight is not a primary concern.

The budget allows for premium materials.

Handling high-power density or pulsed loads.

Choose Aluminum when:

Weight reduction is important.

Cost-effectiveness is a priority.

High-volume production required.

Medium power density applications.