High-Precision Components for Liquid Cooling Systems

Common failures in liquid cold plates, such as interface leaks, uneven flow distribution, and material corrosion, can lead to catastrophic downtime for AI data centers. Dingmetal’s metal components are engineered to address these AI data center infrastructure challenges through superior design, precision machining, and material science.

What is a liquid cooling system for a data center AI?

What solutions do we provide for liquid cold plates?

We specialize in manufacturing high-quality liquid cold plate components, including Barb Fittings and Manifolds. Our core strengths are precision CNC machining(50+ CNC centers), a comprehensive quality control system, and a wide range of customization options.

Our team can provide a variety of precision CNC-machined parts that meet the strict performance and durability requirements of various applications.

What are our advantages as a large metal parts manufacturer?

We are a long-term, second-tier supplier to global leading AI hardware brands. As an experienced metal components manufacturer, our strength lies in our ability to provide large-scale, one-stop delivery without sacrificing precision.

About Dingmetal

Specializing in high-precision metal parts, Dingmetal provides comprehensive, one-stop solutions. Our commitment to quality and innovation has allowed us to become a trusted partner in the medical, telecommunications, and AI data center sectors.

The Metal Parts Experts You Can Rely On

Products

Dingmetal provides customized engineering support to meet the needs of various cooling systems for data centers.

Barb Fitting

A barb fitting is used to create a tight seal between flexible pipes or hoses. Dingmetal's barb fittings are specifically designed to achieve a secure, pressure-resistant seal, eliminating the risk of leaks in liquid cooling loops. They are available in various sizes and materials.

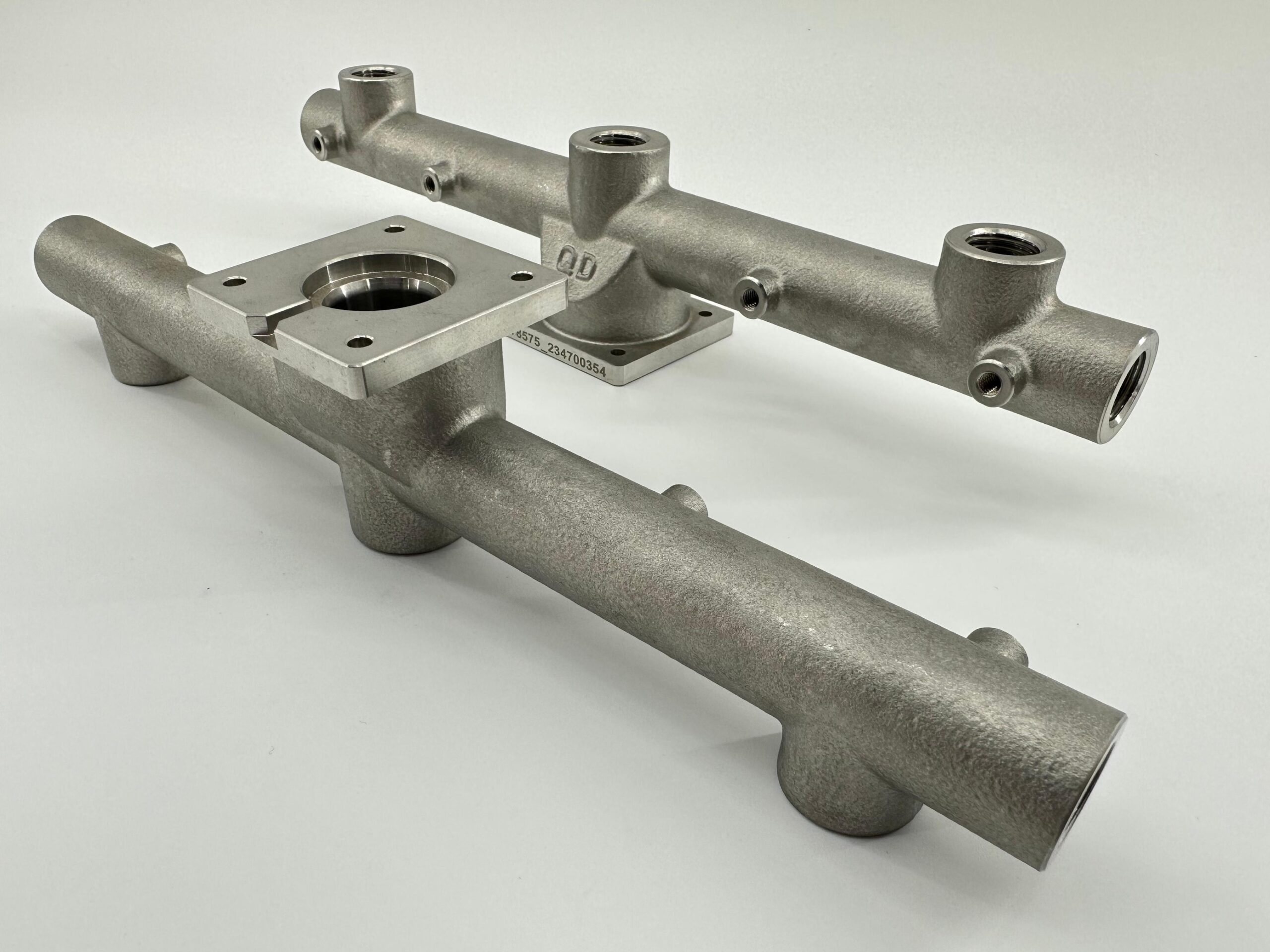

Manifold

A liquid cooling manifold centralizes fluid connections and efficiently distributes coolant to different paths. Our manifolds ensure balanced coolant flow, eliminating hotspots and maximizing the efficiency of liquid cooling equipment in AI data centers.

CNC Precision

CNC precision is the cornerstone of our quality. Our precise CNC machining process delivers parts with strict tolerances and complex geometries for critical applications, ensuring long-lasting and stable performance.

FAQs

What is our sample delivery lead time?

Dingmetal offers rapid prototyping with a sample delivery lead time of 3 to 10 days. For larger orders, we can achieve full production within 15 to 30 days, ensuring on-time delivery without compromising on quality.

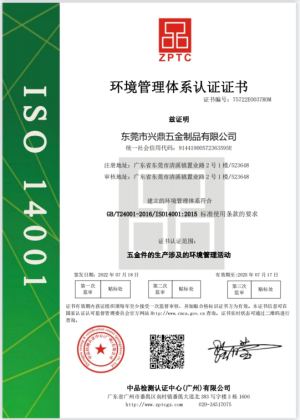

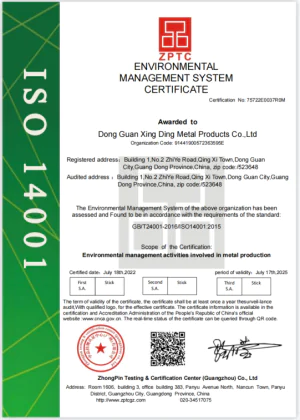

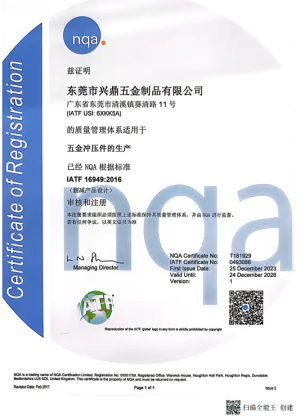

How do we ensure product quality and consistency?

We strictly adhere to ISO 9001, ISO 14001, and IATF 16949 quality management systems.

Our team of engineers has over 20 years of experience and is skilled at managing complex processes like PPAP and APQP.

Additionally, we are equipped with a range of advanced quality inspection devices, including the Tensile Tester, Spectrometer, Hardness Tester, Salt Spray Tester, Shadow Projector, Roughness Tester, Compression Tester, Keyence Laser Measurement System, Coordinate Measuring Machine (CMM), and Thickness Gauge.

What other customized solutions do we support for different application scenarios?

Dingmetal specializes in providing one-stop and customized services for metal parts across various applications. We specialize in manufacturing AI liquid cooling plate components, shielding covers, chassis, heat sinks, and plastic and die-cast automotive parts. We also offer surface treatment and assembly services.

Our Advantages

Exceptional Manufacturing Capabilities Providing Reliable Assurance to Our Global Clients

One-Stop Solution Provider

We offer a complete end-to-end service, from prototyping to mass production, fully covering all your part needs, including liquid cooling system components.

Rapid Prototyping and Mass Production

Our rapid sample service (3–10 days) and quick mass production capabilities (15–30 days) help you accelerate your time to market.

Strict Quality Management System

Our certified production processes ensure every component meets the stringent requirements of demanding environments, including those in AI data centers.

18,000 m²+ Dual Production Facilities

Our two strategic production bases in China and Vietnam, with over 18,000m² of facilities and advanced production lines, guarantee a stable global supply.

Top-tier Clients and Industry Experienc

Dingmetal is trusted by leading industry giants such as SAGEMCOM, BOYD, OSRAM, SCC, LITEON, HARMAN, and USI.

Innovation-driven Professional Team

Our team of engineers has over 20 years of experience, a deep understanding of PPAP and APQP processes, and a focus on technological innovation and breakthroughs.

Let Your Projects Succeed with Reliable Metal Parts

Excellence begins with precision. Contact us for more product photos and technical data.

Quick Links

Products

Contact Information

- Dingmetal Industry Co., Ltd.

- +86 13691922471

- sales1@dingmetal.com

- No.11, Kui Qing Road, Qingxi Town, Dongguan City, Guangdong Province, China

- Vietnam km70 . Highway 5A, Phuong Due village, Kim Xuyen commune, Kim Thanh district, Hai Duong province. Vietnam 03308 km70 . quốc lộ 5A thôn Phương Duệ.xã kim xuyên.huyện kim thành.tỉnh hải dương. việt nam 03308

Copyright © Dingmetal Industry Co., Ltd All Rights Reserved.

- Legal Notice

- Copyright privacy

- Sitemap